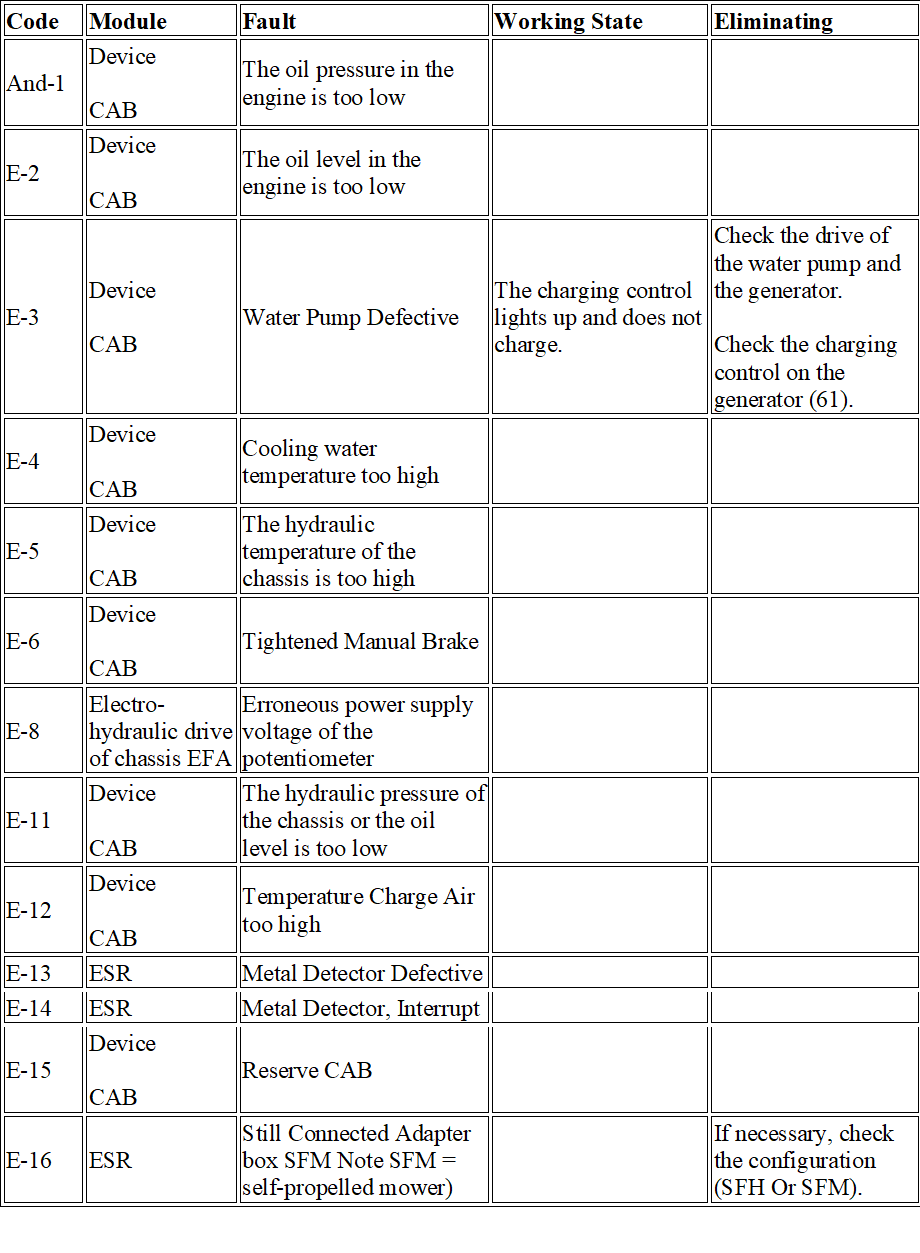

LIST OF ERROR CODES

MFA (A100)

TR1 (A57-1)

TR2 (A57-2)

TR3 (A57-3)

REH (A58)

SFA (A102)

BDG (A103)

ENG (A15)

MFT (A30)

EXT (A62)

DBD (A101)

HYD PVV (A60)

Types of CIS alarms

Fault is indicated by LEDs (A1 to A24), a fault code on CIS display and / or acoustic alarm signal. In case of medium and severe faults, in addition, the STOP lamp lights up traffic informant.

There are three different types of emergency alarms:

Severe / permanent failure Emergency Signal

Malfunction medium / three short alarms

Mild Defect / One Short Emergency Signal

- DESCRIPTION

- TECHNICAL DESCRIPTION

- CAN MESSAGING

- TECHNICAL SPECIFICATIONS

- FUNCTIONAL LOGIC

- SCHEMATIC DIAGRAM

- TECHNICAL SPECIFICATIONS

- FUNCTIONAL LOGIC

- SCHEMATIC DIAGRAM

Claas G1 LIST OF ERROR CODES G2 CONTROL PANEL «WLP» Download

List of A/C error codes

|

Error |

Component concerned |

Type of fault |

«CLAAS component number» |

|

E0 |

Sensor for air temperature inside the cab |

Open circuit |

B086 |

|

E1 |

Pulsed air temperature sensor |

Open circuit |

B087 |

|

E2 |

Solar sensor |

Open circuit |

B224 |

|

E3 |

Pressure switch |

Open circuit |

Z021 |

|

E4 |

Outside air temperature switch |

Open circuit |

B088 |

|

E5 |

Sensor for air temperature inside the cab |

Short circuit |

B086 |

|

E6 |

Pulsed air temperature sensor |

Short circuit |

B087 |

|

E7 |

Solar sensor |

Short circuit |

B224 |

|

E8 |

Compressor |

Open circuit |

Y032 |

|

E9 |

Outside air temperature switch |

Short circuit |

B088 |

|

EA |

Heating power valve |

Valve locked |

V020 |

|

EB |

Heating power valve |

Bad connection |

V020 |

|

EE |

Motor fan regulator |

Overheating |

V020 |

«Cebis» Panel (MFT A30)

MFA (A100)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7500h |

– |

MFA (A100) |

Unable to read tractor |

The multifunction armrest runs |

Check: |

|

Id7502h |

– |

MFA (A100) |

Stabilized power supply 10V |

The contacts of the |

Check: |

|

Id7503h |

– |

MFA (A100) |

Stabilized power supply 5V |

The multifunction armrest is |

Check: |

|

Id7504h |

– |

MFA (A100) |

Signal voltage specified with |

The multifunction armrest is |

Check: |

|

Id7505h |

– |

MFA (A100) |

Signal voltage specified with |

The multifunction armrest is |

Check: |

|

Id7506h |

– |

MFA (A100) |

Signal voltage specified with |

The hand accelerator is |

Check: |

|

Id7507h |

– |

MFA (A100) |

Signal voltage specified by |

The hand accelerator is |

Check: |

|

Id7508h |

– |

MFA (A100) |

Signal voltage specified by |

Lifting is locked. Use external |

Check: |

|

Id7509h |

– |

MFA (A100) |

Signal voltage specified by |

Lifting is locked. Use external |

Check: |

|

Id750Ah |

– |

MFA (A100) |

Signal voltage specified with |

Online command 1 is inactive. |

Check: |

|

Id750Bh |

– |

MFA (A100) |

Signal voltage specified with |

Online command 1 is inactive. |

Check: |

|

Id750Ch |

– |

MFA (A100) |

Signal voltage specified with |

Online command 2 is inactive. |

Check: |

|

Id750Dh |

– |

MFA (A100) |

Signal voltage specified with |

Online command 2 is inactive. |

Check: |

|

Id750Eh |

– |

MFA (A100) |

Signal voltage specified with |

Online command 3 is inactive. |

Check: |

|

Id750Fh |

– |

MFA (A100) |

Signal voltage specified with |

Online command 3 is inactive. |

Check: |

|

Id7510h |

– |

MFA (A100) |

Signal voltage specified with |

Axis 5 of the cross command |

Check: |

|

Id7511h |

– |

MFA (A100) |

Signal voltage specified by |

Axis 5 of the cross command |

Check: |

|

Id7512h |

– |

MFA (A100) |

Signal voltage specified with |

Axis 4 of the cross command |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7513h |

– |

MFA (A100) |

Signal voltage specified by |

Axis 4 of the cross command |

Check: |

|

Id7514h |

– |

MFA (A100) |

Voltage of the signal |

Lifting is locked. Use external |

Check: |

|

Id7515h |

– |

MFA (A100) |

Voltage of the signal |

Lifting is locked. Use external |

Check: |

|

Id7516h |

– |

MFA (A100) |

Voltage of the signal |

Lifting is locked. Use external |

Check: |

|

Id7517h |

– |

MFA (A100) |

Voltage of the signal |

The lifting up mode is inactive. |

Check: |

|

Id7518h |

– |

MFA (A100) |

Voltage of the signal |

The lifting up mode is inactive. |

Check: |

|

Id7519h |

– |

MFA (A100) |

Voltage of the signal |

The lifting up mode is inactive. |

Check: |

|

Id751Ah |

– |

MFA (A100) |

Voltage of the signal |

Lifting is locked. Use external |

Check: |

|

Id751Bh |

– |

MFA (A100) |

Voltage of the signal |

Lifting is locked. Use external |

Check: |

|

Id751Ch |

– |

MFA (A100) |

Voltage of the signal |

Lifting is locked. Use external |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id751Dh |

– |

MFA (A100) |

Voltage of the signal |

The Hexactiv function is |

Check: |

|

Id751Eh |

– |

MFA (A100) |

Voltage of the signal |

The Hexactiv function is |

Check: |

|

Id751Fh |

– |

MFA (A100) |

Voltage of the signal |

The Hexactiv function is |

Check: |

|

Id7520h |

– |

MFA (A100) |

Voltage of the signal |

The transmission neutral |

Check: |

|

Id7521h |

– |

MFA (A100) |

Voltage of the signal |

The transmission neutral |

Check: |

|

Id7522h |

– |

MFA (A100) |

Voltage of the signal |

The transmission neutral |

Check: |

|

Id7523h |

– |

MFA (A100) |

Voltage of the signal |

The engine speed memory 1 is |

Check: |

|

Id7524h |

– |

MFA (A100) |

Voltage of the signal |

The engine speed memory 1 is |

Check: |

|

Id7525h |

– |

MFA (A100) |

Voltage of the signal |

The engine speed memory 1 is |

Check: |

|

Id7526h |

– |

MFA (A100) |

Voltage of the signal |

The engine speed memory 2 is |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7527h |

– |

MFA (A100) |

Voltage of the signal |

The engine speed memory 2 is |

Check: |

|

Id7528h |

– |

MFA (A100) |

Voltage of the signal |

The engine speed memory 2 is |

Check: |

|

Id7529h |

– |

MFA (A100) |

Voltage of the signal |

The engine speed + contact is |

Check: |

|

Id752Ah |

– |

MFA (A100) |

Voltage of the signal |

The engine speed + contact is |

Check: |

|

Id752Bh |

– |

MFA (A100) |

Voltage of the signal |

The engine speed + contact is |

Check: |

|

Id752Ch |

– |

MFA (A100) |

Voltage of the signal |

The engine speed – contact is |

Check: |

|

Id752Dh |

– |

MFA (A100) |

Voltage of the signal |

The engine speed – contact is |

Check: |

|

Id752Eh |

– |

MFA (A100) |

Voltage of the signal |

The engine speed – contact is |

Check: |

|

Id752Fh |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7530h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7531h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7532h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7533h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7534h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7535h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7536h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7537h |

– |

MFA (A100) |

Voltage of the signal |

The Claas Sequence |

Check: |

|

Id7538h |

– |

MFA (A100) |

Voltage of the signal |

Autopilot is inactive. |

Check: |

|

Id7839h |

– |

MFA (A100) |

Voltage of the signal |

Autopilot is inactive. |

Check: |

|

Id753Ah |

– |

MFA (A100) |

Voltage of the signal |

Autopilot is inactive. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id753Bh |

– |

MFA (A100) |

Voltage of the signal |

The function F1 contact is |

Check: |

|

Id753Ch |

– |

MFA (A100) |

Voltage of the signal |

The function F1 contact is |

Check: |

|

Id753Dh |

– |

MFA (A100) |

Voltage of the signal |

The function F1 contact is |

Check: |

|

Id753Eh |

– |

MFA (A100) |

Voltage of the signal |

The function F2 contact is |

Check: |

|

Id753Fh |

– |

MFA (A100) |

Voltage of the signal |

The function F2 contact is |

Check: |

|

Id7540h |

– |

MFA (A100) |

Voltage of the signal |

The function F2 contact is |

Check: |

|

Id7541h |

– |

MFA (A100) |

Signal voltage returned by |

The (+) contact for speed range |

Check: |

|

Id7542h |

– |

MFA (A100) |

Voltage of the signal sent by |

The (+) contact for speed range |

Check: |

|

Id7543h |

– |

MFA (A100) |

Voltage of the signal sent by |

The (+) contact for speed range |

Check: |

|

Id7544h |

– |

MFA (A100) |

Signal voltage returned by |

The (+) contact for speed range |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7545h |

– |

MFA (A100) |

Voltage of the signal sent by |

The (+) contact for speed range |

Check: |

|

Id7546h |

– |

MFA (A100) |

Voltage of the signal sent by |

The (+) contact for speed range |

Check: |

|

Id7547h |

– |

MFA (A100) |

Voltage of the signal |

The manoeuvering gear |

Check: |

|

Id7548h |

– |

MFA (A100) |

Voltage of the signal |

The manoeuvering gear |

Check: |

|

Id7549h |

– |

MFA (A100) |

Voltage of the signal |

The manoeuvering gear |

Check: |

|

Id754Ah |

– |

MFA (A100) |

Voltage of the signal |

The F3 function is inactive. |

Check: |

|

Id754Bh |

– |

MFA (A100) |

Voltage of the signal |

The F3 function is inactive. |

Check: |

|

Id754Ch |

– |

MFA (A100) |

Voltage of the signal |

The F3 function is inactive. |

Check: |

|

Id754Dh |

– |

MFA (A100) |

Voltage of the signal |

The F4 function is inactive. |

Check: |

|

Id754Eh |

– |

MFA (A100) |

Voltage of the signal |

The F4 function is inactive. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id754Fh |

– |

MFA (A100) |

Voltage of the signal |

The F4 function is inactive. |

Check: |

|

Id7550h |

– |

MFA (A100) |

Voltage of the signal |

The Electropilot cross control is |

Check: |

|

Id7551h |

– |

MFA (A100) |

Voltage of the signal |

The Electropilot cross control is |

Check: |

|

Id7552h |

– |

MFA (A100) |

Voltage of the signal |

The Electropilot cross control is |

Check: |

|

Id7553h |

– |

MFA (A100) |

Error on |

Random operation of the |

Check: |

|

Id7554h |

– |

MFA (A100) |

The multifunction armrest |

The backlighting of the |

Check: |

|

Id7555h |

– |

MFA (A100) |

Error on |

Random operation of the |

Check: |

|

Id7556h |

– |

MFA (A100) |

The multifunction armrest no |

The multifunction armrest is |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

TR1 (A57-1)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id75C0h |

301 |

TR1 (A57-1) |

Inconsistent current |

Audio warning:: No. |

Check: |

|

Id75C1h |

302 |

TR1 (A57-1) |

Inconsistent current |

||

|

Id75C2h |

303 |

TR1 (A57-1) |

Supply voltage measured on |

Audio warning:: Yes. |

Check: |

|

Id75C3h |

304 |

TR1 (A57-1) |

Supply voltage measured on |

||

|

Id75C4h |

305 |

TR1 (A57-1) |

Actual current measured on |

Check: |

|

|

Id75C5h |

306 |

TR1 (A57-1) |

Actual current measured on |

||

|

Id75C6h |

307 |

TR1 (A57-1) |

The current consumed by the |

Check: |

|

|

Id75C7h |

308 |

TR1 (A57-1) |

The current consumed by the |

|

Id75C8h |

309 |

TR1 (A57-1) |

The actual current measured |

Audio warning:: Yes. |

Check: |

|

Id75C9h |

310 |

TR1 (A57-1) |

The actual current measured |

||

|

Id75CAh |

311 |

TR1 (A57-1) |

The current sent to the |

Audio warning:: No. |

Check: |

|

Id75CBh |

312 |

TR1 (A57-1) |

The current sent to the |

||

|

Id75CCh |

313 |

TR1 (A57-1) |

Loss of shuttle reverser |

Audio warning:: Yes. |

Check: |

|

Id75CDh |

314 |

TR1 (A57-1) |

Loss of the ENG module |

Check: |

|

|

Id75CEh |

315 |

TR1 (A57-1) |

Loss of theoratical speed |

Audio warning:: No. |

Check: |

|

Id75CFh |

316 |

TR1 (A57-1) |

The voltage of the signal |

Audio warning:: No. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id75D0h |

317 |

TR1 (A57-1) |

The voltage of the signal |

Audio warning:: No. |

Check: |

|

Id75D1h |

318 |

TR1 (A57-1) |

Loss of the theoretical |

Audio warning:: No. |

Check: |

|

Id75D2h |

319 |

TR1 (A57-1) |

Inconsistency between the |

Check: |

|

|

Id75D4h |

321 |

TR1 (A57-1) |

The information provided by |

Audio warning:: Yes or no. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id75D6h |

323 |

TR1 (A57-1) |

The position of the clutch |

Audio warning:: Yes or no. |

Check: |

|

Id75D7h |

324 |

TR1 (A57-1) |

The status of the engaged |

Audio warning:: No. |

Check: |

|

Id75D8h |

325 |

TR1 (A57-1) |

A minimum of 2 range |

||

|

Id75D9h |

326 |

TR1 (A57-1) |

The comparison of the |

||

|

Id75DAh |

327 |

TR1 (A57-1) |

Physical error on the CAN |

Audio warning:: Yes. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id75DBh |

328 |

TR1 (A57-1) |

Unable to read tractor |

Audio warning:: No. |

Configure the «Auto 5» modules using |

|

Id75DCh |

329 |

TR1 (A57-1) |

Problem saving parameters |

Check: |

|

|

Id75DDh |

330 |

TR1 (A57-1) |

The unit 12 V supply voltage |

Check: |

|

|

Id75DEh |

331 |

TR1 (A57-1) |

The 10 V supply to the |

– |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id75DFh |

332 |

TR1 (A57-1) |

Short circuit or open circuit |

Audio warning:: Yes. |

Check: |

|

Id75E0h |

333 |

TR1 (A57-1) |

Short circuit or open circuit |

Check: |

|

|

Id75E1h |

334 |

TR1 (A57-1) |

Short circuit or open circuit |

Check: |

|

|

Id75E2h |

335 |

TR1 (A57-1) |

Short circuit or open circuit |

Check: |

|

|

Id75E3h |

336 |

TR1 (A57-1) |

Inconsistant «Auto 5» analog |

Audio warning:: No. |

Check: |

|

Id75E4h |

337 |

TR1 (A57-1) |

Inconsistency between the |

Audio warning:: Yes. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id75F5h |

354 |

TR1 (A57-1) |

Short circuit on range A |

Audio warning:: No. |

Check: |

|

Id75F6h |

355 |

TR1 (A57-1) |

Short circuit on range B |

||

|

Id75F7h |

356 |

TR1 (A57-1) |

Short circuit on range C |

||

|

Id75F8h |

357 |

TR1 (A57-1) |

Short circuit on range D |

||

|

Id75F9h |

358 |

TR1 (A57-1) |

Calibration of the Revershift |

– |

|

|

Id75FAh |

359 |

TR1 (A57-1) |

Stack overload. |

– |

|

|

Id75FBh |

360 |

TR1 (A57-1) |

Paddle in forward gear (or |

Audio warning:: Yes or no. |

Check: |

|

Id75FCh |

361 |

TR1 (A57-1) |

Paddle in forward gear (or |

||

|

Id75FDh |

362 |

TR1 (A57-1) |

Paddle in forward gear and |

||

|

Id75FEh |

363 |

TR1 (A57-1) |

Palette position not detected. |

||

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

TR2 (A57-2)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7620h |

401 |

TR2 (A57-2) |

Pressure of high-pressure |

Audio warning:: Yes. |

Check: |

|

Id7621h |

402 |

TR2 (A57-2) |

Pressure of high-pressure |

||

|

Id7622h |

403 |

TR2 (A57-2) |

Pressure of high-pressure |

Audio warning:: No. |

Check: |

|

Id7623h |

404 |

TR2 (A57-2) |

Supply problem with high |

Audio warning:: Yes. |

Check: |

|

Id7624h |

405 |

TR2 (A57-2) |

78 bar < pressure of high |

Audio warning:: No. |

Check: |

|

Id7625h |

406 |

TR2 (A57-2) |

High-pressure brake |

Check: |

|

Id7626h |

407 |

TR2 (A57-2) |

High-pressure brake sensor |

Audio warning:: Yes. |

Check: |

|

Id7627h |

408 |

TR2 (A57-2) |

High-pressure brake |

Check: |

|

|

Id7628h |

409 |

TR2 (A57-2) |

Loss of the Hexactiv function |

Audio warning:: No. |

Check: |

|

Id7629h |

410 |

TR2 (A57-2) |

Full left steering position not |

Return to normal mode by |

Turn the wheels fully to the left. Validate |

|

Id762Ah |

411 |

TR2 (A57-2) |

Wheel in line position not |

Return to normal mode by |

Set the wheels straight. Validate by |

|

Id762Bh |

412 |

TR2 (A57-2) |

Steering right-hand |

Return to normal mode by |

Turn the wheels fully to the right. Validate |

|

Id762Ch |

413 |

TR2 (A57-2) |

Voltage of the steering angle |

– |

Diagnostic lamp blinks. |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id762Dh |

414 |

TR2 (A57-2) |

Loss of the ENG module |

Audio warning:: Yes. |

Check: |

|

Id762Eh |

415 |

TR2 (A57-2) |

Loss of the theoretical |

Audio warning:: Yes. |

Check: |

|

Id762Fh |

416 |

TR2 (A57-2) |

Error on high pressure |

Pressure < 70 bar during |

Pump for 15 seconds. Start the tractor. |

|

Id7630h |

417 |

TR2 (A57-2) |

Error on high pressure |

Pressure < 70 bar at least 2 |

Pump for 15 seconds. Start the tractor. |

|

Id7631h |

418 |

TR2 (A57-2) |

Loss of gear upshift control |

Audio warning:: Yes. |

Check: |

|

Id7632h |

419 |

TR2 (A57-2) |

Loss of the downshifting |

||

|

Id7633h |

420 |

TR2 (A57-2) |

Loss of the up and down |

||

|

Id7634h |

421 |

TR2 (A57-2) |

Error on high pressure |

Pressure exceeds the |

Pump for 15 seconds. Start the tractor. |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7635h |

422 |

TR2 (A57-2) |

The transmission oil |

Audio warning:: Yes. |

Check: |

|

Id7636h |

423 |

TR2 (A57-2) |

Error on high pressure |

Pressure ranges between 78 |

Pump for 15 seconds. Start the tractor. |

|

Id7637h |

424 |

TR2 (A57-2) |

Error on high pressure |

The accumulator inflates too |

Cancel the fault, If the error appears |

|

Id7638h |

425 |

TR2 (A57-2) |

Error on high pressure |

The pressure sensor (B233) is |

Pump for 15 seconds. Start the tractor. |

|

Id7639h |

426 |

TR2 (A57-2) |

Error on high pressure |

Pressure < 70 bars during 0,2 to |

Pump for 15 seconds. Start the tractor. |

|

Id763Ah |

427 |

TR2 (A057-2) |

Physical error on the CAN |

Audio warning:: Yes. |

Check: |

|

Id763Bh |

428 |

TR2 (A57-2) |

Unable to read tractor |

Audio warning:: No. |

Configure the «Auto 5» modules using |

|

Id763Ch |

429 |

TR2 (A57-2) |

Problem saving parameters |

Check: |

|

|

Id763Dh |

430 |

TR2 (A57-2) |

The unit 12 V supply voltage |

Check: |

|

|

Id763Eh |

431 |

TR2 (A57-2) |

The 10 V supply to the |

– |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7640h |

433 |

TR2 (A57-2) |

Calibration of the Power |

Bad measurement. Engine |

Recalibrate |

|

Id7641h |

434 |

TR2 (A57-2) |

During operation Powerboost |

Engine speed sensor 1 of 2 |

Bad measurement. The tractor returns to |

|

Id7643h |

436 |

TR2 (A57-2) |

Inconsistant «Auto 5» analog |

Audio warning:: No. |

Check: |

|

Id7645h |

438 |

TR2 (A57-2) |

Supply voltage measured on |

Audio warning:: Yes. |

Check: |

|

Id7646h |

439 |

TR2 (A57-2) |

Actual current measured on |

Check: |

|

|

Id7647h |

440 |

TR2 (A57-2) |

The current consumed by |

Audio warning:: Yes. |

Check: |

|

Id7648h |

441 |

TR2 (A57-2) |

The actual current measured |

Check: |

|

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7649h |

442 |

TR2 (A57-2) |

The current sent to solenoid |

Audio warning:: Yes. |

Check: |

|

Id764Ah |

443 |

TR2 (A57-2) |

Supply voltage measured on |

Check: |

|

|

Id764Bh |

444 |

TR2 (A57-2) |

Actual current measured on |

Check: |

|

|

Id764Ch |

445 |

TR2 (A57-2) |

The current consumed by |

Audio warning:: Yes. |

Check: |

|

Id764Dh |

446 |

TR2 (A57-2) |

The actual current measured |

Check: |

|

|

Id764Eh |

447 |

TR2 (A57-2) |

The current sent to solenoid |

Audio warning:: Yes. |

Check: |

|

Id764Fh |

448 |

TR2 (A57-2) |

Supply voltage measured on |

Check: |

|

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7650h |

449 |

TR2 (A57-2) |

Actual current measured on |

Audio warning:: Yes. |

Check: |

|

Id7651h |

450 |

TR2 (A57-2) |

The current consumed by |

Check: |

|

|

Id7652h |

451 |

TR2 (A57-2) |

The actual current measured |

Check: |

|

|

Id7653h |

452 |

TR2 (A57-2) |

The current sent to solenoid |

Check: |

|

|

Id7654h |

453 |

TR2 (A57-2) |

No 20 bar low pressure |

Audio warning:: Yes. |

Check: |

|

Id7655h |

454 |

TR2 (A57-2) |

Calibration of the |

– |

– |

|

Id7656h |

455 |

TR2 (A57-2) |

Calibration of the right |

||

|

Id7657h |

456 |

TR2 (A57-2) |

Calibration of the center |

||

|

Id7658h |

457 |

TR2 (A57-2) |

Calibration of the left position |

||

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7659h |

458 |

TR2 (A57-2) |

Loss of the information on |

The manoeuvering gear |

Check: |

|

Id765Ah |

459 |

TR2 (A57-2) |

Stack overload- Random |

Random operation. |

– |

|

Id765Bh |

460 |

TR2 (A57-2) |

Limitation of the |

The Claas Power Management |

Check: |

|

Id765Ch |

461 |

TR2 (A57-2) |

Limitation of the |

The Claas Power Management |

Check: |

|

Id765Dh |

462 |

TR2 (A57-2) |

Claas Power Management |

The Claas Power Management |

Check: |

|

Id765Eh |

463 |

TR2 (A57-2) |

Claas Power Management |

The lowest power curve is |

Check: |

|

Id78B0h |

840 |

TR2 (A57-2) |

Tranmission module TR2 |

Gear selection command |

Check: |

|

Id78B1h |

841 |

TR2 (A57-2) |

The gearbox is disconnected |

Sequence stopped. |

Wait for the sequence to be relaunched. |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id78B2h |

842 |

TR2 (A57-2) |

Tranmission module TR2 |

DrivestickDisconnected |

Check: |

|

Id78B3h |

843 |

TR2 (A57-2) |

Field end maneuvering gear |

Sequence stopped. |

Wait for the sequence to be relaunched. |

|

Id78B4h |

844 |

TR2 (A57-2) |

Tranmission module TR2 |

Automatic gear shifting |

Check: |

|

Id78B5h |

845 |

TR2 (A57-2) |

Automatic gear shifting |

Sequence stopped. |

Wait for the sequence to be relaunched. |

|

Id78B6h |

846 |

TR2 (A57-2) |

Tranmission module TR2 |

4 wheel drive disconnected |

Check: |

|

Id78B7h |

847 |

TR2 (A57-2) |

Tranmission module TR2 |

Differential lock disconnected |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

TR3 (A57-3)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7680h |

501 |

TR3 (A57-3) |

PTO clutch skidding high. |

The PTO is off. |

Check: |

|

Id7681h |

502 |

TR3 (A57-3) |

Open circuit on the rear PTO |

The PTO is off. |

Check: |

|

Id7682h |

503 |

TR3 (A57-3) |

Short-circuit to 12V of the |

The PTO is off. |

Check: |

|

Id7683h |

504 |

TR3 (A57-3) |

Short-circuit to ground of the |

The PTO is off. |

Check: |

|

Id7684h |

505 |

TR3 (A57-3) |

Drop in engine speed (during |

The PTO is off. |

Check: |

|

Id7685h |

506 |

TR3 (A57-3) |

Overspeed in economy. |

The PTO is off. |

Check: |

|

Id7686h |

507 |

TR3 (A57-3) |

Battery fault out of range (10 |

The PTO is off. |

Check: |

|

Id7687h |

508 |

TR3 (A57-3) |

The information on the |

The PTO is off. |

Check: |

|

Id7688h |

509 |

TR3 (A57-3) |

Eegine speed information on |

The PTO is off. |

Check: |

|

Id7689h |

510 |

TR3 (A57-3) |

Clutch time of the PTO too |

The PTO continues running in |

Check: |

|

Id768Ah |

511 |

TR3 (A57-3) |

Loss of information from the |

The PTO continues running in |

Check: |

|

Id768Bh |

512 |

TR3 (A57-3) |

Regulation of the PTO’s |

The PTO continues running in |

Check: |

|

Id768Ch |

513 |

TR3 (A57-3) |

Operating code (no |

Normal operation. |

– |

|

Id768Dh |

514 |

TR3 (A57-3) |

Operating code (no |

Normal operation. |

– |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id768Eh |

515 |

TR3 (A57-3) |

Confirmation of the |

– |

– |

|

Id768Fh |

516 |

TR3 (A57-3) |

Open circuit of automatic |

The automatic hand brake is |

Check: |

|

Id7690h |

517 |

TR3 (A57-3) |

The automatic hand brake |

The automatic hand brake is |

Check: |

|

Id7691h |

518 |

TR3 (A57-3) |

Open circuit on the automatic |

Cannot disengage the |

Check: |

|

Id7692h |

519 |

TR3 (A57-3) |

Short-circuit to ground of the |

Cannot disengage the |

Check: |

|

Id7693h |

520 |

TR3 (A57-3) |

Information of the automatic |

Automatic hand brake contact |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7694h |

521 |

TR3 (A57-3) |

Short-circuit to ground of the |

Cannot engage the automatic |

Check: |

|

Id7695h |

522 |

TR3 (A57-3) |

Open circuit on the automatic |

Cannot engage the automatic |

Check: |

|

Id7696h |

523 |

TR3 (A57-3) |

Short-circuit to 12V of the |

Cannot engage the automatic |

Check: |

|

Id7697h |

524 |

TR3 (A57-3) |

Short-circuit at 12V of the |

Normal operation. |

Check: |

|

Id7698h |

525 |

TR3 (A57-3) |

Wear sensor of the automatic |

Wear of the automatic hand |

Check: |

|

Id7699h |

526 |

TR3 (A57-3) |

Automatic hand brake wear |

The automatic hand brake wear |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id769Ah |

527 |

TR3 (A57-3) |

Open circuit on the front PTO |

The front PTO is stopped. |

Check: |

|

Id769Bh |

528 |

TR3 (A57-3) |

Short-circuit at the 12V of the |

The front PTO is stopped. |

Check: |

|

Id769Ch |

529 |

TR3 (A57-3) |

Short-circuit to ground of the |

The front PTO is stopped. |

Check: |

|

Id769Dh |

530 |

TR3 (A57-3) |

Short-circuit at the 12V of the |

Rear PTO brake inactive. |

Check: |

|

Id769Eh |

531 |

TR3 (A57-3) |

Short-circuit at the 12V of the |

Rear PTO automation inactive. |

Check: |

|

Id769Fh |

532 |

TR3 (A57-3) |

This code appears upon |

Problem Park-Lock. |

The Park-Lock is inoperative. |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id78BAh |

850 |

TR3 (A57-3) |

Rear power take-off |

The power take-off is |

After 20 seconds, the tractor initializes, |

|

Id78BBh |

851 |

TR3 (A57-3) |

Tranmission module TR3 |

Rear power take-off |

Check: |

|

Id78BCh |

852 |

TR3 (A57-3) |

Front power take-off |

The power take-off is |

After 20 seconds, the tractor initializes, |

|

Id78BDh |

853 |

TR3 (A57-3) |

Tranmission module TR3 |

Front power take-off |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

REH (A58)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id76A0h |

711 |

REH (A58) |

Open circuit on the supply of |

Lifting is inactive. |

Check: |

|

Id76A1h |

712 |

REH (A58) |

Open circuit on the supply of |

Lifting is inactive. |

Check: |

|

Id76A2h |

713 |

REH (A58) |

Short-circuit at 12V or to |

Lifting is inactive. |

Check: |

|

Id76A3h |

714 |

REH (A58) |

Voltage of the external lifting |

Lifting is inactive. |

Check: |

|

Id76A5h |

716 |

REH (A58) |

12V supply of the REH |

Lifting is inactive. |

Check: |

|

Id76A7h |

718 |

REH (A58) |

The REH (A58) lifting module |

Lifting is inactive. |

Check: |

|

Id76ABh |

722 |

REH (A58) |

Voltage of the signal of |

Lifting is locked. Use external |

Check: |

|

Id76ACh |

723 |

REH (A58) |

The REH (A58) lifting module |

Lifting is locked. Use external |

Check: |

|

Id76ADh |

724 |

REH (A58) |

Voltage of the high stop |

Lifting is locked. Use external |

Check: |

|

Id76B1h |

728 |

REH (A58) |

Error on the rear lifting mode |

Rear lifting is blocked. |

Restart the tractor. |

|

Id76B2h |

729 |

REH (A58) |

The stop lifting contact of the |

Lifting is locked. Use external |

Check: |

|

Id76B4h |

731 |

REH (A58) |

Signal voltage of the right |

Load control and transport |

Check: |

|

Id76B5h |

732 |

REH (A58) |

Signal voltage of the left load |

Load control and transport |

Check: |

|

Id76B6h |

733 |

REH (A58) |

Voltage of the transport |

Load control and transport |

Check: |

|

Id76B7h |

734 |

REH (A58) |

Voltage of the down speed |

Control of the down speed |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id76B8h |

735 |

REH (A58) |

The REH lifting module has |

Load control and skid control |

Check: |

|

Id76B9h |

736 |

REH (A58) |

Voltage of the load control |

Load control is inactive. |

Check: |

|

Id76BAh |

737 |

REH (A58) |

Voltage of the skid instruction |

Skid control is inactive. |

Check: |

|

Id76BBh |

738 |

REH (A58) |

The REH lifting module has |

Skid control is inactive (or |

Check: |

|

Id76BCh |

739 |

REH (A58) |

The REH (A58) lifting module |

The lifting up mode is inactive. |

Check: |

|

Id76BEh |

741 |

REH (A58) |

The right load sensor is in |

The right load sensor is ignored. |

Check: |

|

Id76C0h |

743 |

REH (A58) |

Calibrating…. |

Lifting calibration…. |

None. |

|

Id76C1h |

744 |

REH (A58) |

Lifting parameters have been |

The lifting parameters have |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id78CFh |

871 |

REH (A58) |

Rear lifting disconnected |

Rear lifting is inoperative. |

After 20 seconds, the tractor initializes, |

|

Id78D0h |

872 |

REH (A58) |

The lifting module REH (A58) |

Rear lifting disconnected. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

SFA (A102)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7580h |

900 |

SFA (A102) |

The cab suspension |

The compressor (Y334) is |

Check the supply voltage of the |

|

Id7581h |

901 |

SFA (A102) |

Compressor wear. |

The number of cycles has |

The compressor is running. |

|

Id7582h |

902 |

SFA (A102) |

The cab suspension |

The compressor has been |

Active damping. |

|

Id7583h |

903 |

SFA (A102) |

Cab suspension failure. |

No message from the left-hand |

Maximum tractor speed 15 km/h. |

|

Id7584h |

904 |

SFA (A102) |

Cab suspension failure. |

No message from the right |

Maximum tractor speed 15 km/h. |

|

Id76D0h |

613 |

SFA (A102) |

Unable to read tractor |

Non functional suspension |

Check: |

|

Id76D8h |

621 |

SFA (A102) |

Short-circuit on the On/Off |

Non functional suspension |

Check: |

|

Id76D9h |

622 |

SFA (A102) |

Short-circuit on the supply of |

Non functional suspension |

Check: |

|

Id76DAh |

623 |

SFA (A102) |

Short-circuit on the supply of |

Non functional suspension |

Check: |

|

Id76DBh |

624 |

SFA (A102) |

Short-circuit on the supply of |

Non functional suspension |

Check: |

|

Id76DCh |

625 |

SFA (A102) |

Short-circuit on the supply of |

Non functional suspension |

Check: |

|

Id76DDh |

626 |

SFA (A102) |

Open circuit on the On/Off |

Non functional suspension |

Check: |

|

Id76DEh |

627 |

SFA (A102) |

Open circuit on the down On/ |

Non functional suspension |

Check: |

|

Id76DFh |

628 |

SFA (A102) |

Open circuit on the transfer |

Non functional suspension |

Check: |

|

Id76E0h |

629 |

SFA (A102) |

Open circuit on the transfer |

Non functional suspension |

Check: |

|

Id76E2h |

631 |

SFA (A102) |

Open circuit on the |

Non functional suspension |

Check: |

|

Id76E3h |

632 |

SFA (A102) |

Short-circuit to ground of the |

Non functional suspension |

Check: |

|

Id76E4h |

633 |

SFA (A102) |

Short-circuit to ground of the |

Non functional suspension |

Check: |

|

Id76E5h |

634 |

SFA (A102) |

Short circuit to ground of the |

Non functional suspension |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id76E6h |

635 |

SFA (A102) |

Short-circuit to ground of the |

Non functional suspension |

Check: |

|

Id76E7h |

636 |

SFA (A102) |

Short-circuit to ground of the |

Non functional suspension |

Check: |

|

Id76E8h |

637 |

SFA (A102) |

Open circuit, short-circuit to |

Non functional suspension |

Check: |

|

Id76E9h |

638 |

SFA (A102) |

Short-circuit on the supply of |

Non functional suspension |

Check: |

|

Id76EAh |

639 |

SFA (A102) |

Open circuit, short-circuit to |

Non functional suspension |

Check: |

|

Id76ECh |

641 |

SFA (A102) |

Short-circuit to supply of the |

Non functional suspension |

Check: |

|

Id76EDh |

642 |

SFA (A102) |

Supply voltage too low (< |

Non functional suspension |

Check: |

|

Id78C4h |

860 |

SFA (A102) |

Front suspended axle |

The front axle is inoperative. |

After 20 seconds, the tractor initializes, |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

BDG (A103)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id76F0h |

– |

BDG (A103) |

Confirmation of engine |

– |

– |

|

Id76F1h |

– |

BDG (A103) |

No message was transmitted |

The front axle suspension is |

Check: |

|

Id76F2h |

– |

BDG (A103) |

No message was transmitted |

The hydraulic module |

Check: |

|

Id76F3h |

– |

BDG (A103) |

No message was transmitted |

The external function module |

Check: |

|

Id76F4h |

– |

BDG (A103) |

No message was transmitted |

The Z+ module and its |

Check: |

|

Id76F5h |

– |

BDG (A103) |

No message was transmitted |

The CVT module and its |

Check: |

|

Id76F6h |

– |

BDG (A103) |

No message was transmitted |

The Cebis terminal module |

Check: |

|

Id76F7h |

– |

BDG (A103) |

No message has been |

The WLP (A104) working light |

Check: |

|

Id76F8h |

– |

BDG (A103) |

No message has been |

The MFA (A100) multifunction |

Check: |

|

Id76F9h |

– |

BDG (A103) |

No message has been |

The DBD (A101) instrument |

Check: |

|

Id76FAh |

– |

BDG (A103) |

No message has been |

The ENG (A15) engine module |

Check: |

|

Id76FBh |

– |

BDG (A103) |

No message has been |

The TR1 (A57-1) transmission |

Check: |

|

Id76FCh |

– |

BDG (A103) |

No message has been |

The TR2 (A57-2) transmission |

Check: |

|

Id76FDh |

– |

BDG (A103) |

No message has been |

The TR3 (A57-3) transmission |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id76FEh |

– |

BDG (A103) |

No message has been |

The REH (A58) lifting module |

Check: |

|

Id76FFh |

– |

BDG (A103) |

Short-circuit to the 12V on |

– |

Check: |

|

Id7700h |

– |

BDG (A103) |

Short-circuit to the ground on |

– |

Check: |

|

Id7701h |

– |

BDG (A103) |

The BDG module no longer |

– |

Check: |

|

Id7702h |

– |

BDG (A103) |

Short-circuit to the 12V on |

– |

Check: |

|

Id7703h |

– |

BDG (A103) |

Short-circuit to the ground on |

– |

Check: |

|

Id7704h |

– |

BDG (A103) |

The BDG module no longer |

– |

Check: |

|

Id7705h |

– |

BDG (A103) |

Engine controller |

The engine controller is |

After 20 seconds, the tractor initializes, |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7706h |

– |

BDG (A103) |

Tranmission module TR2 |

– |

Sequence stopped. Wait for the sequence |

|

Id7707h |

– |

BDG (A103) |

Message missing on the |

Functions unavailable. |

Back to normal mode when the message |

|

Id7708h |

– |

BDG (A103) |

Message missing on the |

Functions unavailable. |

Back to normal mode when the message |

|

Id7709h |

– |

BDG (A103) |

Message missing on the |

Functions unavailable. |

Back to normal mode when the message |

|

Id770Ah |

– |

BDG (A103) |

Message missing on the |

Functions unavailable. |

Back to normal mode when the message |

|

Id770Bh |

– |

BDG (A103) |

Message missing on the |

Functions unavailable. |

Back to normal mode when the message |

|

Id770Ch |

– |

BDG (A103) |

Message missing on the |

No message from the ITE |

Back to normal mode when the message |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

ENG (A15)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7710h |

190 00 |

ENG (A15) |

Extreme engine overspeed. |

The fuel supply of the common |

Abnormal use of the engine. |

|

Id7711h |

676 03 |

ENG (A15) |

High voltage on the glow |

Difficult start. |

Check: |

|

Id7712h |

676 04 |

ENG (A15) |

No return voltage on the glow |

Difficult start in extreme cold. |

Check: |

|

Id7713h |

898 09 |

ENG (A15) |

The ENG (A15) engine |

The engine remains in idle |

Check: |

|

Id7714h |

1568 02 |

ENG (A15) |

The ENG (A15) engine |

The Claas Sequence |

Check: |

|

Id7715h |

2004 09 |

ENG (A15) |

Communication error on the |

The engine remains in idle |

Check: |

|

Id7716h |

2000 13 |

ENG (A15) |

Engine/transmission |

The engine stays in idle speed |

Check: |

|

Id7717h |

2005 09 |

ENG (A15) |

Communication error on the |

The engine remains in idle |

Check: |

|

Id7718h |

97 03 |

ENG (A15) |

Voltage of the signal high |

The engine runs normally |

Check: |

|

Id7719h |

97 04 |

ENG (A15) |

Voltage of the signal low |

The engine runs normally |

Check: |

|

Id771Ah |

97 16 |

ENG (A15) |

Presence of water detected |

Engine power is reduced to |

Empty the decanter prefilter. Restart the |

|

Id771Bh |

102 02 |

ENG (A15) |

Air pressure in the intake |

The engine runs normally |

Check: |

|

Id771Ch |

102 03 |

ENG (A15) |

High intake manifold air |

The engine runs normally |

Check: |

|

Id771Dh |

102 04 |

ENG (A15) |

Low air pressure at intake |

The engine runs normally |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id771Eh |

103 00 |

ENG (A15) |

Turbocharger speed |

The ENG (A15) engine |

Check: |

|

Id771Fh |

103 05 |

ENG (A15) |

Intensity of the turbocharger |

The engine runs normally |

Check: |

|

Id7720h |

103 06 |

ENG (A15) |

Intensity of the turbocharger |

The engine runs normally |

Check: |

|

Id7721h |

103 08 |

ENG (A15) |

Turbocharger speed non |

The engine runs normally |

Check: |

|

Id7722h |

103 31 |

ENG (A15) |

Turbocharger speed missing |

The engine runs normally |

Check: |

|

Id7723h |

105 00 |

ENG (A15) |

Air mix temeprature |

The ENG (A15) engine |

Check: |

|

Id7724h |

105 03 |

ENG (A15) |

Input voltage of the mixed air |

The engine runs normally |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7725h |

105 04 |

ENG (A15) |

Input temperature of the |

The engine runs normally |

Check: |

|

Id7726h |

105 15 |

ENG (A15) |

Temperature of mixed air |

The engine runs normally |

Check: |

|

Id7727h |

105 16 |

ENG (A15) |

Temperature of mixed air |

The ENG (A15) engine |

Check: |

|

Id7728h |

108 02 |

ENG (A15) |

Internal barometric pressure |

The ENG (A15) engine |

Check: |

|

Id7729h |

110 00 |

ENG (A15) |

Engine coolant temperature |

The ENG (A15) engine |

Check: |

|

Id772Ah |

110 03 |

ENG (A15) |

Input voltage of the engine |

The ENG (A15) engine coolant |

Check: |

|

Id772Bh |

110 04 |

ENG (A15) |

Input voltage of the engine |

The ENG (A15) engine coolant |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id772Ch |

110 15 |

ENG (A15) |

Temperature of the engine |

The engine runs normally. |

Check: |

|

Id772Dh |

110 16 |

ENG (A15) |

Temperature of the engine |

The ENG (A15) engine |

Check: |

|

Id772Eh |

110 17 |

ENG (A15) |

Engine coolant temeprature |

The engine runs normally. |

Check: |

|

Id772Fh |

157 03 |

ENG (A15) |

Input voltage of the fuel |

The ENG (A15) engine |

Check: |

|

Id7730h |

157 04 |

ENG (A15) |

Input voltage of the fuel |

The ENG (A15) engine |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7731h |

157 10 |

ENG (A15) |

Loss of pressure in the fuel |

The engine cannot start or |

Check: |

|

Id7732h |

157 17 |

ENG (A15) |

Fuel pressure in the common |

The engine will not start. |

Check: |

|

Id7733h |

158 17 |

ENG (A15) |

Error when powering off the |

The ENG (A15) engine |

Check: |

|

Id7734h |

174 00 |

ENG (A15) |

Fuel temperature |

The ENG (A15) engine |

Check: |

|

Id7735h |

174 03 |

ENG (A15) |

Fuel temperature input |

The ENG (A15) engine |

Check: |

|

Id7736h |

174 04 |

ENG (A15) |

Fuel temperature input |

The ENG (A15) engine |

Check: |

|

Id7737h |

174 16 |

ENG (A15) |

Fuel temperature moderately |

The engine runs normally. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7738h |

412 00 |

ENG (A15) |

Temperature of cooled |

The ENG (A15) engine |

Check: |

|

Id7739h |

412 03 |

ENG (A15) |

Input voltage of the |

The engine runs normally |

Check: |

|

Id773Ah |

412 04 |

ENG (A15) |

Input voltage of cooled |

The engine runs normally |

Check: |

|

Id773Bh |

412 15 |

ENG (A15) |

Temperature of cooled |

The ENG (A15) engine |

Check: |

|

Id773Ch |

412 16 |

ENG (A15) |

Temperature of cooled |

The ENG (A15) engine |

Check: |

|

Id773Dh |

611 03 |

ENG (A15) |

Short-circuit on the power |

The engine misfires and/or |

Check: |

|

Id773Eh |

611 04 |

ENG (A15) |

Short-circuit to ground of the |

The engine misfires and/or |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id773Fh |

627 01 |

ENG (A15) |

Supply voltage of the ENG |

The engine may fail to start. |

Check: |

|

Id7740h |

629 13 |

ENG (A15) |

Error of the ENG engine |

The engine will not start. |

Check: |

|

Id7741h |

636 02 |

ENG (A15) |

Signal of the position sensor |

The start time is extended. |

Check: |

|

Id7742h |

636 05 |

ENG (A15) |

Intensity of the position |

The engine runs normally |

Check: |

|

Id7743h |

636 06 |

ENG (A15) |

Intensity of the position |

The engine runs normally |

Check: |

|

Id7744h |

636 08 |

ENG (A15) |

No signal from the position |

The engine runs normally |

Check: |

|

Id7745h |

636 10 |

ENG (A15) |

Format of the position signal |

The start time is extended. |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7746h |

637 02 |

ENG (A15) |

Signal of the crankshaft |

The ENG (A15) engine |

Check: |

|

Id7747h |

637 05 |

ENG (A15) |

Intensity of the crankshaft |

The engine runs normally |

Check: |

|

Id7748h |

637 06 |

ENG (A15) |

Intensity of the crankshaft |

The engine runs normally |

Check: |

|

Id7749h |

637 07 |

ENG (A15) |

Position of the crankshaft/ |

The engine may stall, then |

Check: |

|

Id774Ah |

637 08 |

ENG (A15) |

No signal from the crankshaft |

The ENG (A15) engine |

Check: |

|

Id774Bh |

637 10 |

ENG (A15) |

Format of the crankshaft |

The ENG (A15) engine |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id774Ch |

641 04 |

ENG (A15) |

Turbocharger actuator error. |

The engine may have a power |

Check: |

|

Id774Dh |

641 12 |

ENG (A15) |

Communication error |

The actuator approaches the |

Check: |

|

Id774Eh |

641 13 |

ENG (A15) |

Error in the values of the |

The engine runs normally. |

Check: |

|

Id774Fh |

641 16 |

ENG (A15) |

Temperature of the |

The engine runs normally. |

Check: |

|

Id7750h |

651 02 |

ENG (A15) |

Reference of the injector of |

The engine may run with |

Check: |

|

Id7751h |

651 05 |

ENG (A15) |

Open circuit on the electronic |

The engine will run with |

Check: |

|

Id7752h |

651 06 |

ENG (A15) |

Short-circuit of the electronic |

The engine will run with |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7753h |

651 07 |

ENG (A15) |

Mechanical failure of the |

The engine will run with |

Check: |

|

Id7754h |

651 13 |

ENG (A15) |

QR code non valid of the |

The engine may run with |

Check: |

|

Id7755h |

652 02 |

ENG (A15) |

Reference of the injector of |

The engine may run with |

Check: |

|

Id7756h |

652 05 |

ENG (A15) |

Open circuit on the electronic |

The engine will run with |

Check: |

|

Id7757h |

652 06 |

ENG (A15) |

Short-circuit of the electronic |

The engine will run with |

Check: |

|

Id7758h |

652 07 |

ENG (A15) |

Mechanical failure of the |

The engine will run with |

Check: |

|

Id7759h |

652 13 |

ENG (A15) |

QR code non valid of the |

The engine may run with |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id775Ah |

653 02 |

ENG (A15) |

Reference of the injector of |

The engine may run with |

Check: |

|

Id775Bh |

653 05 |

ENG (A15) |

Open circuit on the electronic |

The engine will run with |

Check: |

|

Id775Ch |

653 06 |

ENG (A15) |

Short-circuit of the electronic |

The engine will run with |

Check: |

|

Id775Dh |

653 07 |

ENG (A15) |

Mechanical failure of the |

The engine will run with |

Check: |

|

Id775Eh |

653 13 |

ENG (A15) |

QR code non valid of the |

The engine may run with |

Check: |

|

Id775Fh |

654 02 |

ENG (A15) |

Reference of the injector of |

The engine may run with |

Check: |

|

Id7760h |

654 05 |

ENG (A15) |

Open circuit on the electronic |

The engine will run with |

Check: |

|

Id7761h |

654 06 |

ENG (A15) |

Short-circuit of the electronic |

The engine will run with |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7762h |

654 07 |

ENG (A15) |

Mechanical failure of the |

The engine will run with |

Check: |

|

Id7763h |

654 13 |

ENG (A15) |

QR code non valid of the |

The engine may run with |

Check: |

|

Id7764h |

655 02 |

ENG (A15) |

Reference of the injector of |

The engine may run with |

Check: |

|

Id7765h |

655 05 |

ENG (A15) |

Open circuit on the electronic |

The engine will run with |

Check: |

|

Id7766h |

655 06 |

ENG (A15) |

Short-circuit of the electronic |

The engine will run with |

Check: |

|

Id7767h |

655 07 |

ENG (A15) |

Mechanical failure of the |

The engine will run with |

Check: |

|

Id7768h |

655 13 |

ENG (A15) |

QR code non valid of the |

The engine may run with |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7769h |

656 02 |

ENG (A15) |

Reference of the injector of |

The engine may run with |

Check: |

|

Id776Ah |

656 05 |

ENG (A15) |

Open circuit on the electronic |

The engine will run with |

Check: |

|

Id776Bh |

656 06 |

ENG (A15) |

Short-circuit of the electronic |

The engine will run with |

Check: |

|

Id776Ch |

656 07 |

ENG (A15) |

Mechanical failure of the |

The engine will run with |

Check: |

|

Id776Dh |

656 13 |

ENG (A15) |

QR code non valid of the |

The engine may run with |

Check: |

|

Id776Eh |

1136 00 |

ENG (A15) |

Temperature of the engine |

The ENG (A15) engine |

Check: |

|

Id776Fh |

1136 16 |

ENG (A15) |

Temperature of the engine |

The ENG (A15) engine |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7770h |

1172 03 |

ENG (A15) |

Input voltage of the |

The ENG (A15) engine |

Check: |

|

Id7771h |

1172 04 |

ENG (A15) |

Input voltage of the |

The ENG (A15) engine |

Check: |

|

Id7772h |

1180 00 |

ENG (A15) |

Intake air temperature of the |

The ENG (A15) engine |

Check: |

|

Id7773h |

1180 16 |

ENG (A15) |

Turbocharger intake air |

The ENG (A15) engine |

Check: |

|

Id7774h |

1347 03 |

ENG (A15) |

Intensity of the high pressure |

The engine will run abnormally |

Check: |

|

Id7775h |

1347 05 |

ENG (A15) |

Disparity of intensity of the |

The engine’s power increases |

Check: |

|

Id7776h |

1347 07 |

ENG (A15) |

Error in fuel pressure of the |

The engine calculator instructs |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7777h |

1569 31 |

ENG (A15) |

Reduction of fuel input. |

The ENG (A15) engine |

Check the following error codes: |

|

Id7778h |

2630 00 |

ENG (A15) |

Fresh air intake temperature |

The ENG (A15) engine |

Check: |

|

Id7779h |

2630 03 |

ENG (A15) |

Input voltage of the fresh air |

The ENG (A15) engine |

Check: |

|

Id777Ah |

2630 04 |

ENG (A15) |

Input voltage of the fresh air |

The ENG (A15) engine |

Check: |

|

Id777Bh |

2630 15 |

ENG (A15) |

Input voltage of the fresh air |

The engine runs normally. |

Check: |

|

Id777Ch |

2630 16 |

ENG (A15) |

Fresh air intake temperature |

The ENG (A15) engine |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id777Dh |

2659 02 |

ENG (A15) |

Flow rate/temperature gap |

The engine runs normally |

Check: |

|

Id777Eh |

2659 15 |

ENG (A15) |

Flow rate of recycled exhaust |

— |

Check: |

|

Id777Fh |

2659 17 |

ENG (A15) |

Flow rate of recycled exhaust |

The ENG (A15) engine |

Check: |

|

Id7780h |

2790 16 |

ENG (A15) |

Turbocharger exit |

The ENG (A15) engine |

Check: |

|

Id7781h |

2791 02 |

ENG (A15) |

Position of the EGR exhasut |

The ENG (A15) engine |

Check: |

|

Id7782h |

2791 03 |

ENG (A15) |

Signal of the EGR exhaust |

This error code produces the |

Check: |

|

Id7783h |

2791 04 |

ENG (A15) |

Signal of the EGR exhaust |

This error code produces the |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7784h |

2791 07 |

ENG (A15) |

Command error of the |

If the |

Check: |

|

Id7785h |

2791 13 |

ENG (A15) |

EGR exhaust gas recycling |

If the |

Check: |

|

Id7786h |

2791 31 |

ENG (A15) |

Calibration error of the EGR |

The engine runs normally while |

Check: |

|

Id7787h |

2795 07 |

ENG (A15) |

Gap in the position of the |

The ENG (A15) engine |

Check: |

|

Id7788h |

3509 03 |

ENG (A15) |

Reference voltage of the fuel |

The ENG (A15) engine |

Check: |

|

Id7789h |

3509 04 |

ENG (A15) |

Reference voltage of the fuel |

The ENG (A15) engine |

Check: |

|

Id778Ah |

3510 03 |

ENG (A15) |

Reference voltage (5V) of |

The ENG (A15) engine |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id778Bh |

3510 04 |

ENG (A15) |

Reference voltage (5V) of |

The ENG (A15) engine |

Check: |

|

Id778Ch |

3511 03 |

ENG (A15) |

Reference voltage (5V) high. |

The ENG (A15) engine |

Check: |

|

Id778Dh |

3511 04 |

ENG (A15) |

Reference voltage (5V) low. |

The ENG (A15) engine |

Check: |

|

Id778Eh |

3512 03 |

ENG (A15) |

Reference voltage (5V) high. |

The ENG (A15) engine |

Check: |

|

Id778Fh |

3512 04 |

ENG (A15) |

Reference voltage (5V) low. |

The ENG (A15) engine |

Check: |

|

Id7790h |

3513 03 |

ENG (A15) |

Reference voltage (5V) of |

The ENG (A15) engine |

Check: |

|

Id7791h |

3513 04 |

ENG (A15) |

Reference voltage (5V) of |

The ENG (A15) engine |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

MFT (A30)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7877h |

– |

MFT (A30) |

Internal error of the Cebis |

Random operation of the Cebis |

Check: |

|

Id7878h |

– |

MFT (A30) |

Brightness sensor of the |

Automatic control of brightness |

Check: |

|

Id7879h |

– |

MFT (A30) |

Internal temperature sensor |

The internal temperature sensor |

Check: |

|

Id787Ah |

– |

MFT (A30) |

Voltage delivered by the |

The loudspeaker of the Cebis |

Check: |

|

Id787Bh |

– |

MFT (A30) |

Voltage delivered by the |

The loudspeaker of the Cebis |

Check: |

|

Id787Ch |

– |

MFT (A30) |

Short-circuit to the 12V on |

The Cebis terminal no longer |

Check: |

|

Id787Dh |

– |

MFT (A30) |

Short-circuit to the ground on |

Check: |

|

|

Id787Eh |

– |

MFT (A30) |

The CLAAS vehicle CAN bus |

Check: |

|

|

Id787Fh |

– |

MFT (A30) |

The Cebis terminal no longer |

Check: |

EXT (A62)

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7880h |

– |

EXT (A62) |

Short-circuit to the 12V on |

– |

Check: |

|

Id7881h |

– |

EXT (A62) |

Short-circuit to the ground on |

– |

Check: |

|

Id7882h |

– |

EXT (A62) |

The EXT module no longer |

– |

Check: |

|

Id7883h |

– |

EXT (A62) |

The CLAAS vehicle CAN bus |

– |

Check: |

|

Id7884h |

– |

EXT (A62) |

Short-circuit to the 12V on |

– |

Check: |

|

Id7885h |

– |

EXT (A62) |

Short-circuit to the ground on |

– |

Check: |

|

Id7886h |

– |

EXT (A62) |

The EXT module no longer |

– |

Check: |

|

Id7887h |

– |

EXT (A62) |

The ISO CAN bus |

– |

Check: |

|

Id7888h |

– |

EXT (A62) |

Short-circuit to ground of the |

– |

Check: |

|

Id7889h |

– |

EXT (A62) |

Short-circuit to ground of the |

– |

Check: |

|

Id788Ah |

– |

EXT (A62) |

The EXT external function |

The actual speed information is |

Check: |

|

Id788Bh |

– |

EXT (A62) |

The EXT external function |

The theroretical speed |

Check: |

|

Id788Ch |

– |

EXT (A62) |

The EXT external function |

The PTO speed information is |

Check: |

|

Id788Dh |

– |

EXT (A62) |

The EXT external function |

The lifting high position |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id788Eh |

– |

EXT (A62) |

The EXT external function |

The lifting position information |

Check: |

|

Id788Fh |

– |

EXT (A62) |

The EXT external function |

No information is available over |

Check: |

|

Id7890h |

– |

EXT (A62) |

The external function module |

The engine speed information is |

Check: |

|

Id7891h |

– |

EXT (A62) |

The external function module |

The position light information is |

Check: |

|

Id7892h |

– |

EXT (A62) |

The external function module |

The left stop light information is |

Check: |

|

Id7893h |

– |

EXT (A62) |

The external function module |

The right stop light information |

Check: |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id7894h |

– |

EXT (A62) |

The external function module |

The information from the WLP |

Check: |

|

Id7895h |

– |

EXT (A62) |

The external function module |

The rear power take-off |

Check: |

|

Id78A0h |

– |

EXT (A62) |

You are about to launch a |

– |

– |

|

Id78A1h |

– |

EXT (A62) |

The CSM sequence is |

CSM sequence interrupted as |

– |

|

Id78A2h |

– |

EXT (A62) |

The CSM sequence cannot |

The CSM sequence does not |

Speed must exceed 1,5 km/h |

|

Id78A3h |

– |

EXT (A62) |

The version of the CSM |

The sequence has been |

– |

|

Id78A4h |

– |

EXT (A62) |

Fault of the «Claas Sequence |

– |

Check: |

|

Id78A5h |

– |

EXT (A62) |

Switch the CSM (S177) |

– |

– |

|

Error code |

Native |

Sender |

Designation |

Cause/System response |

Comment/Solution |

|

Id78A6h |

– |

EXT (A62) |

The CSM sequence is |

The CSM sequence is |

– |

|

Id78A7h |

– |

EXT (A62) |

The CSM sequence is |

The CSM sequence is |

– |

|

Id78A8h |

– |

EXT (A62) |

The CSM sequence is |

The CSM sequence does not |

Speed must exceed 1,5 km/h |

|

Id78A9h |

– |

EXT (A62) |

The CSM sequence is |

The CSM sequence is |

– |

|

Id78AAh |

– |

EXT (A62) |

One of the functions to be |

Entry rejected |

Check: |

|

Id78ABh |

– |

EXT (A62) |

Communication problem |

No response after validation. |