Все современные копировальные аппараты, мфу и принтеры Kyocera имеют возможность диагностировать все узлы устройства в режиме запуска и во время работы аппарата. По этому, если во время включения или во время работы произошел сбой, то техника Kyocera сможет сообщить о наличии ошибки.

В большинстве случаев у аппаратов Kyocera код ошибки отображается на дисплее, в остальных случаях тип ошибки зависит от последовательности и количества миганий индикаторов.

Если Ваш копировальный аппарат, МФУ или принтер Kyocera выдал на дисплее некий код, то узнать причину, описание возникновения ошибки, а так же в каком узле аппарата стоит искать проблему, Вы можете в этом разделе выбрав интересующую модель из списка.

Но диагностика не решит проблему сбоя аппарата, для этого лучше обратиться к профессиональным и опытным сервисным специалистам компании Kyomart! Позвоните нам по телефону

8 (343) 288-23-45 или отправьте запрос на электронную почту: sales@kyomart.ru , и мы обязательно свяжемся с Вами в кратчайшие сроки.

Код ошибки Описание ошибки Причина ошибки 0030 FAX control PWB system error

Processing with the fax software was disabled due to a hardware problem. Defective FAX control PWB. 0060 Engine PWB type error Defective engine sub PCB. 0070 FAX control PWB incompatible detection error

Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted. Defective FAX software

Defective FAX control PWB. 0100 Backup memory device error Defective flash memory. 0120 MAC address data error

For data in which the MAC address is invalid. Defective main PWB.

Defective flash memory.

Defective engine PWB. 0130 Backup memory read/write error (main PWB) Defective flash memory.

Defective main PWB. 0140 Backup memory data error (main PWB) Defective flash memory.

Defective main PWB. 0150 Backup memory read/write error (engine PWB)

Detecting engine PWB EEPROM communication error. Improper installation engine PWB EEPROM.

Defective engine PWB.

Device damage of EEPROM. 0160 Backup memory data error (engine PWB) Defective flash memory.

Defective engine PWB. 0170 Billing counting error

A checksum error is detected in the main and engine backup memories for the billing counters. Data damage of EEPROM.

Defective PWB. 0180 Machine number mismatch

Machine number of main and engine does not match. Data damage of EEPROM. 0320 I/O CPU communication error

A communication error is detected 10 times in succession. Defective PWB. 0630 DMA error DMA transmission of image data does not complete within the specified period of time. Poor contact in the connector terminals. Defective main PWB. 0800 Image processing error

JAM05 is detected twice. Defective main PWB. 0830 FAX control PWB flash program area checksum error

A checksum error occurred with the program of the FAX control PWB. Defective FAX software.

Defective FAX control PWB. 0840 Faults of RTC

The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. The battery is disconnected from the main PWB.

Defective main PWB. 0870 FAX control PWB to main PWB high capacity data transfer error

High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times. Improper installation FAX control PWB.

Defective FAX control PWB or main PWB. 0920 Fax file system error

The backup data is not retained for file system abnormality of flash memory of the FAX control PWB. Defective FAX control PWB. 1010 Lift motor error

After cassette 1 is inserted, lift sensor does not turn on within 12 s. This error is detected four times successively. Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of the lift motor.

Defective lift motor.

Defective engine PWB. 1020 PF lift motor error (paper feeder)

After cassette 2 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected four times successively. Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of the PF lift motor 1.

Defective PF lift motor 1.

Defective PF main PWB. 1030 PF lift motor error (paper feeder)

After cassette 3 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected four times successively. Defective bottom plate elevation mechanism in the cassette.

Defective connector cable or poor contact in the connector.

Defective drive transmission system of the PF lift motor 2.

Defective PF lift motor 2.

Defective PF main PWB. 1800 Paper feeder communication error

A communication error is detected 10 times in succession. Improper installation paper feeder.

Defective connector cable or poor contact in the connector.

Defective engine PWB.

Defective PF main PWB. 1900 Paper feeder EEPROM error

When writing the data, the write data and the read data is not continuously in agreement 5 times. Defective PF main PWB.

Device damage of EEPROM. 2000 Main motor steady-state error

Stable OFF is detected for 1 s continuously after main motor stabilized. Defective connector cable or poor contact in the connector.

Defective drive transmission system of the main motor.

Defective main motor.

Defective engine PWB. 2010 Main motor drive error

The main motor is not stabilized within 2 s after driving starts. Defective connector cable or poor contact in the connector.

Defective drive transmission system of the main motor.

Defective main motor.

Defective engine PWB. 2101 Developer motor K steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the developer motor K stabilizes. Defective connector cable or poor contact in the connector.

Defective drive transmission system.

Defective motor.

Defective PWB. 2102 Developer motor YCM steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the developer motor YCM stabilizes. Defective connector cable or poor contact in the connector.

Defective drive transmission system.

Defective motor.

Defective PWB. 2111 Developer motor K startup error

Developer motor K is not stabilized within 2 s since the motor is activated. Defective connector cable or poor contact in the connector

Defective drive transmission system.

Defective motor.

Defective PWB. 2112 Developer motor YCM startup error

Developer motor YCM is not stabilized within 2 s since the motor is activated. Defective connector cable or poor contact in the connector

Defective drive transmission system.

Defective motor.

Defective PWB. 2300 Fuser motor steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the fuser motor stabilizes. Defective connector cable or poor contact in the connector.

Defective drive transmission system.

Defective motor.

Defective PWB. 2310 Fuser motor startup error

Fuser motor is not stabilized within 2 s since the motor is activated. Defective connector cable or poor contact in the connector.

Defective drive transmission system.

Defective motor.

Defective PWB. 2550 Conveying motor steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the conveying motor stabilizes. Defective connector cable or poor contact in the connector.

Defective drive transmission system.

Defective motor.

Defective PWB. 2560 Conveying motor startup error

Conveying motor is not stabilized within 2 s since the motor is activated. Defective connector cable or poor contact in the connector.

Defective drive transmission system.

Defective motor.

Defective PWB. 2600 PF drive motor error (paper feeder)

When the PF drive motor is driven, error signal is detected continuously for 1 s. Defective connector cable or poor contact in the connector.

Defective drive transmission system of the PF drive motor.

Defective PF drive motor.

Defective PF main PWB. 2700 TC belt motor error

When the TC belt motor is driven, error signal is detected continuously for 1 s. Defective connector cable or poor contact in the connector.

Defective drive transmission system of the PF drive motor.

Defective PF drive motor.

Defective PF main PWB. 3100 ISU home position error

The home position is not correct when the power is turned on or at the start of copying using the table. Defective connector cable or poor contact in the connector.

Defective home position sensor.

Defective ISU motor.

Defective CCD PWB.

Defective engine PWB. 3200 Exposure lamp error

When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s. Defective connector cable or poor contact in the connector.

Defective exposure lamp.

Defective CCD PWB.

Defective main PWB. 3500 Communication error between scanner and ASIC

An error code is detected 3 times in succession. Defective connector cable or poor contact in the connector.

Defective CCD PWB.

Defective main PWB. 3600 Scanner sequence error Defective main PWB or engine PWB. 4000 Polygon motor synchronization error

The polygon motor is not stabilized within 10 s after driving starts. Defective connector cable or poor contact in the connector.

Defective polygon motor.

Defective engine PWB. 4001 Polygon motor (K) steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the polygon motor (K) stabilizes. Defective connector cable or poor contact in the connector.

Defective motor

Defective PWB. 4002 Polygon motor (С) steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the polygon motor (С) stabilizes. Defective connector cable or poor contact in the connector.

Defective motor

Defective PWB. 4003 Polygon motor (M) steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the polygon motor (M) stabilizes. Defective connector cable or poor contact in the connector.

Defective motor

Defective PWB. 4004 Polygon motor (Y) steady-state error

The rated speed signal detected the stability OFF continuously for 1 s after the polygon motor (Y) stabilizes. Defective connector cable or poor contact in the connector.

Defective motor

Defective PWB. 4010 Polygon motor steady-state error

Stable OFF is detected for 1 s continuously after polygon motor stabilized. Defective connector cable or poor contact in the connector.

Defective polygon motor.

Defective engine PWB. 4011 Polygon motor (K) startup error

Polygon motor (K) is not stabilized within 10 s since the motor is activated. Defective connector cable or poor contact in the connector.

Defective motor.

Defective PWB. 4012 Polygon motor (C) startup error

Polygon motor (C) is not stabilized within 10 s since the motor is activated. Defective connector cable or poor contact in the connector.

Defective motor.

Defective PWB. 4013 Polygon motor (M) startup error

Polygon motor (M) is not stabilized within 10 s since the motor is activated. Defective connector cable or poor contact in the connector.

Defective motor.

Defective PWB. 4014 Polygon motor (Y) startup error

Polygon motor (Y) is not stabilized within 10 s since the motor is activated. Defective connector cable or poor contact in the connector.

Defective motor.

Defective PWB. 4100 BD initialization error

BD is not detected within 1 s after polygon motor stabilized. Defective connector cable or poor contact in the connector.

Defective APC PWB.

Defective BD PWB.

Defective main PWB. 4600 LSU cleaning motor error

When the LSU cleaning motor is driven, an error signal is detected continuously for 1 s. Defective connector cable or poor contact in the connector.

Defective drive transmission system.

Defective motor. Defective PWB. 4700 VIDEO ASIC device error Defective connector cable or poor contact in the connector.

Defective main PWB or engine PWB. 4950 LSU CPU communication error

A communication error is detected 10 times in succession. Defective connector cable or poor contact in the connector.

Defective PWB. 6000 Broken fuser heater wire

The detected temperature of fuser thermistor does not reach the specified temperature (ready indication temperature) after the fuser heater has been turned on continuously for 60 s in warming up. The fusing temperature at 7 seconds and 20 seconds since fuser temperature control has occurred differs by 43°C/109.4°F or less. Defective connector cable or poor contact in the connector.

Deformed connector pin.

Defective triac.

Fuser thermostat triggered.

Broken fuser heater wire.

Defective engine PWB. 6000

6020

6030

6050 Broken fuser heater wire

Abnormally high fuser thermistor temperature Broken fuser thermistor wire Abnormally low fuser thermistor temperature Deformed connector pin.

Defective triac. 6020 Abnormally high fuser thermistor temperature

The fuser thermistor detects a temperature higher than 230°C/446°F continuously for 40 ms. High fuser temperature signal detects a temperature of 255°C/491°F continuously for 40 ms. Deformed connector pin.

Defective triac.

Shorted fuser thermistor.

Defective engine PWB. 6030 Broken fuser thermistor wire

A/D value of the fuser thermistor exceeds 251 bit continuously for 7 s during warming up. Defective connector cable or poor contact in the connector.

Deformed connector pin.

Defective triac.

Defective fuser thermistor.

Defective engine PWB 6050 Abnormally low fuser thermistor temperature

As the stable temperature has reached the second time, the decrease in the fuser thermistor temperature of 60°C/140°F or greater is detected for one second. Deformed connector pin.

Defective triac.

Defective fuser thermistor

Defective fuser heater.

Defective engine PWB. 6120 Abnormally high fuser thermistor 3 (press roller) temperature

The fuser temperature exceeds 200 °C/392 °F for 1 s. Deformed connector pin.

Defective IH PWB.

Defective fuser thermistor.

Defective engine PWB. 6130 Fuser thermistor 3 (press roller) break error Fuser thermistor 3 detects a temperature of -14 °C/6.8 °F . Fuser thermistor 3 does not reach 30° C/86 °F even after20 s during warming up. Defective connector cable or poor contact in the connector

Deformed connector pin.

Defective IH PWB.

Defective fuser thermistor.

Defective engine PWB. 6150 Abnormally low fuser thermistor 3 (press roller) temperature

The fuser temperature lower than 30 °C/86 °F is detected continuously for 1 s. Deformed connector pin.

Defective fuser thermistor

Defective fuser heater.

Defective engine PWB. 6200 Broken fuser edge heater wire

Fuser thermistor 1 does not reach 50° C/122 °F even after20 s during warming up. The detected temperature of fuser thermistor1 does not reach the specified temperature (ready indication temperature) for 20 s in warming up after reaching 50° C/122 °F. Defective connector cable or poor contact in the connector.

Deformed connector pin.

Fuser thermostat triggered.

Broken fuser heater wire.

Defective engine PWB. 6220 Abnormally high fuser thermistor 1 (edge) temperature

The fuser temperature exceeds 240 °C/464 °F for 1 s Defective connector cable or poor contact in the connector.

Deformed connector pin.

Fuser thermostat triggered.

Broken fuser heater wire.

Defective engine PWB. 6230 Fuser thermistor 1 (edge) break error

During warming up a hearter, fuser thermistor 2 detects a temperature of 100 °C/212 °F or higher and, fuser thermistor 1 detects a temperature of 37 °C/99 °F or lower. Defective connector cable or poor contact in the connector.

Deformed connector pin.

Fuser thermostat triggered.

Broken fuser heater wire.

Defective engine PWB. 6250 Abnormally low fuser thermistor 1 (edge) temperature

The fuser temperature lower than 100 °C/212 °F is detected continuously for 1 s during printing. The fuser temperature lower than 50 °C/122 °F is detected continuously for 1 s during pre-heating. Defective connector cable or poor contact in the connector.

Deformed connector pin.

Fuser thermostat triggered.

Broken fuser heater wire.

Defective engine PWB. 6400 Zero-cross signal error

While fuser heater control is performed, the zero-cross signal is not input within 3 s. Defective connector cable or poor contact in the connector

Defective power source PWB or engine PWB. 6410 Fuser unit type mismatch problem

Absence of the fuser unit is detected. Fuser unit connector inserted incorrectly.

Different type of the fuser unit is installed. 6600 Belt rotation error

The belt was detected to stop for 1 s continuously during motor remote is on. Defective fuser motor.

Defective IH belt.

Defective IH PWB.

Defective engine PWB. 7101 Toner sensor K error Defective Developer unit.

Defective PWB. 7102 Toner sensor C error Defective Developer unit.

Defective PWB. 7103 Toner sensor M error Defective Developer unit.

Defective PWB. 7104 Toner sensor Y error Defective Developer unit.

Defective PWB. 7401 Developing unit K type mismatch problem

Absence of the developing unit K is detected. Developing unit connector inserted incorrectly.

Different type of the developing unit is installed.

Defective PWB. 7402 Developing unit C type mismatch problem

Absence of the developing unit C is detected. Developing unit connector inserted incorrectly.

Different type of the developing unit is installed.

Defective PWB. 7403 Developing unit M type mismatch problem

Absence of the developing unit M is detected. Developing unit connector inserted incorrectly.

Different type of the developing unit is installed.

Defective PWB. 7404 Developing unit Y type mismatch problem

Absence of the developing unit Y is detected. Developing unit connector inserted incorrectly.

Different type of the developing unit is installed.

Defective PWB. 7411 Drum unit K type mismatch problem

Absence of the drum unit K is detected. Drum unit connector inserted incorrectly.

Different type of the drum unit is installed.

Defective PWB. 7412 Drum unit C type mismatch problem

Absence of the drum unit C is detected. Drum unit connector inserted incorrectly.

Different type of the drum unit is installed.

Defective PWB. 7413 Drum unit M type mismatch problem

Absence of the drum unit M is detected. Drum unit connector inserted incorrectly.

Different type of the drum unit is installed.

Defective PWB. 7414 Drum unit Y type mismatch problem

Absence of the drum unit Y is detected. Drum unit connector inserted incorrectly.

Different type of the drum unit is installed.

Defective PWB. 7420 Transfer belt unit type mismatch problem

Absence of the transfer belt unit is detected. Transfer belt unit connector inserted incorrectly.

Different type of the transfer belt unit is installed.

Defective PWB. 7601 ID sensor 1 (front) error Defective ID sensor.

Defective PWB. 7602 ID sensor 2 (rear) error Defective ID sensor.

Defective PWB. 7611 ID sensor (K) density error

When ID sensor 2 detected CTD is 500 or less. Defective ID sensor.

Defective PWB. 7612 ID sensor (C) density error

When ID sensor 2 detected CTD is 500 or less. Defective ID sensor.

Defective PWB. 7613 ID sensor (M) density error

When ID sensor 2 detected CTD is 500 or less. Defective ID sensor.

Defective PWB. 7614 ID sensor (Y) density error

When ID sensor 2 detected CTD is 500 or less. Defective ID sensor.

Defective PWB. 7620 ID sensor timing error

Color registration correction was failed. Defective ID sensor.

Defective PWB. 7800 Broken external thermistor wire

The thermistor output value is 0.3 V or less. Defective connector cable or poor contact in the connector.

Defective temperature sensor. 7810 Short-circuited external thermistor wire

The thermistor output value is 3 V or more. Defective connector cable or poor contact in the connector.

Defective temperature sensor. 7900 Drum unit EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Defective connector cable or poor contact in the connector.

Defective drum unit. 7901 Drum K EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Defective connector cable or poor contact in the connector.

Defective drum unit. 7902 Drum C EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Defective connector cable or poor contact in the connector.

Defective drum unit. 7903 Drum M EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Defective connector cable or poor contact in the connector.

Defective drum unit. 7904 Drum Y EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Defective connector cable or poor contact in the connector.

Defective drum unit. 7910 Developer unit EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Defective connector cable or poor contact in the connector.

Defective developer unit. 7911 Developing unit K EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Poor contact in the connector terminals.

Defective developing PWB. 7912 Developing unit C EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Poor contact in the connector terminals.

Defective developing PWB. 7913 Developing unit M EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Poor contact in the connector terminals.

Defective developing PWB. 7914 Developing unit Y EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs eight times successively. Mismatch between writing data and reading data occurs eight times successively. Poor contact in the connector terminals.

Defective developing PWB. 8030 Tray upper limit detection problem (document finisher)

When the tray elevation motor raises a tray, the ON status of the tray upper limit sensor is detected. Defective connector cable or poor contact in the connector.

Defective tray upper limit sensor, paper surface sensor 1/2.

Defective DF main PWB. 8040 Belt problem (document finisher)

The belt sensor does not turn on/off within specified time of the belt solenoid turning on. Defective connector cable or poor contact in the connector.

Defective belt sensor.

Defective belt solenoid.

Defective DF main PWB. 8140 Tray elevation motor problem (document finisher)

The tray low limit sensor or paper surface sensor 1/2 cannot be detected to be on within 10 s since the tray elevation motor is activated. Defective connector cable or poor contact in the connector.

Defective connector cable or poor contact in the connector.

The tray elevation motor malfunctions.

Defective tray lower limit sensor, paper surface sensor 1/2.

Defective DF main PWB. 8210 Stapler problem (document finisher)

Jam 7012 or 7023 is indicated. Defective connector cable of staple or poor contact in the connector.

The stapler is blocked with a staple.

The stapler is broken

Defective DF main PWB. 8320 Adjustment motor 2 problem (document finisher)

The adjustment sensor 2 does not turn on/off within specified time of the adjustment motor 2 turning on. Defective connector cable or poor contact in the connector.

Defective adjustment sensor 2.

Defective adjustment motor 2.

Defective DF main PWB. 8330 Adjustment motor 1 problem (document finisher)

The adjustment sensor 1 does not turn on/off within specified time of the adjustment motor 1 turning on. Defective connector cable or poor contact in the connector.

Defective adjustment sensor 1.

Defective adjustment motor 1. 8350 Roller motor problem (document finisher)

The roller sensor does not turn on/off within specified time of the roller motor turning on. Defective DF main PWB.

Defective connector cable or poor contact in the connector.

Defective roller sensor.

Defective roller motor.

Defective DF main PWB. 8360 Slide motor problem (document finisher)

The slide sensor does not turn on/off within specified time of the slide motor turning on. Defective connector cable or poor contact in the connector.

Defective slide sensor.

Defective slide motor.

Defective DF main PWB. 8460 EEPROM problem (document finisher)

Reading from or writing to EEPROM cannot be performed. Defective EEPROM or DF main PWB. 8800 Document finisher communication error

A communication error is detected 10 times in succession. Defective connector cable or poor contact in the connector

Defective DF main PWB.

Defective engine PWB. 8830 Bridge communication error (document finisher)

A communication error is detected 10 times in succession. Defective connector cable or poor contact in the connector.

Defective bridge PWB.

Defective engine PWB. 8990 Document finisher communication error Defective connector cable or poor contact in the connector.

Defective DF main PWB.

Defective bridge PWB. 9000 Document processor communication error

A communication error is detected 10 times in succession. Defective connector cable or poor contact in the connector.

Defective DP main PWB. 9060 DP EEPROM error Read and write data does not match. Data in the specified area of the backup memory does not match the specified values. Defective DP main PWB.

Device damage of EEPROM. 9500 BRU communication error IPU PWB error 9510 BRU PWB error IPU PWB error 9520 BRU PWB data error IPU PWB error F000 Main PWB — operation panel PWB communication error Defective main PWB.

Defective operation panel PWB. F010 Main PWB checksum error Defective main PWB. F040 Main PWB — print engine communication error Defective main PWB.

Defective engine PWB. F050 Print engine ROM checksum error Defective engine PWB.

-

Catalog

-

Sign In

-

Contacts

-

Forum

-

Eng

- Error Codes

- Kyocera

- FSC8520MFP

- Code 4600

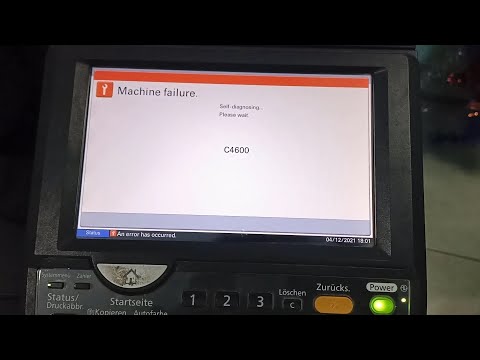

- Code: 4600

- Description: LSU cleaning motor error

When the LSU cleaning motor is driven, an error signal is detected continuously for 1 s. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system. Defective motor. Defective PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity of the connector cable. If none, replace the cable. LSU cleaning motor and LSU connect PWB(YC11) LSU connect PWB and engine PWB(YC12)

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective motor. Replace the LSU cleaning motor.

Defective PWB. Replace the engine PWB or LSU connect PWB check for correct operation.

-

08-15-2016

#1

Junior Member

- Rep Power

- 0

Kyocera P6035cdn error C4600

Hi Guys,

I’ve been stuck with a Kyocera ECOsys P6035cdn that is driving me crazy!!!, it keeps giving me a C4600 error which is the LSU cleaning motor error.To date:

-> I’ve upgraded to the latest available firmware,

-> Followed the LSU cleaning motor service bulletins and greased the relevant gears and shafts,

-> Replaced the Engine Relay as prescribed in the service manual.

STILL NO JOY!!!

Anybody have any other options for me to try or ideas other than matches and petrol?

Thanks.

-

08-16-2016

#2

Technician

- Rep Power

- 14

Re: Kyocera P6035cdn error C4600

there is bulletin for the same code

-

08-16-2016

#3

Junior Member

- Rep Power

- 0

Re: Kyocera P6035cdn error C4600

@TECHKYO, Yes…I saw the service bulletin and did the modifications but the error msg: C4600 still comes back.

-

08-16-2016

#4

Trusted Tech

50+ Posts

- Rep Power

- 18

Re: Kyocera P6035cdn error C4600

unplug the cleaning motor from the pcb

It has been working so far.

-

10-12-2016

#5

Junior Member

- Rep Power

- 0

Re: Kyocera P6035cdn error C4600

-

11-14-2018

#6

Re: Kyocera P6035cdn error C4600

I’ve got a couple of M6535cidn in a very dusty warehouse with the same problem. I’ve unplugged the cleaning motors on both, which got rid of the codes, but I have to manually clean them every few weeks, which is getting old!

If replacing the LSUs would make a permanent fix I would gladly do it, but I haven’t seen anything about modifications to them.

So, it’s been a while since you replaced both LSUs… Did that permanently fix the problem???

Thanks for your reply,

Robert B.

Atlanta, GA

-

11-14-2018

#7

Trusted Tech

50+ Posts

- Rep Power

- 26

Re: Kyocera P6035cdn error C4600

We have modified several of this series machines with some success. We have found that the cleaning motor will need to be replaced and possibly the left connect board to eliminate the error code. While replacing the motor, you can modify the lasers with mylar pieces to help the cleaners get on the glass of the laser. This has eliminated the problem on several machines for us. I will post a link to a video that we made describing the modification. I have sent this to Kyocera with no response from them except that they have tried it also with success, but never bothered to let anyone know about it.

https://drive.google.com/open?id=1Bn…ZO9ccRJiJP0WL5

-

01-22-2019

#8

Junior Member

- Rep Power

- 0

Re: Kyocera P6035cdn error C4600

I tried all of the above, but I wasn’t settling on having to go back once a month to pull the 4 devs, 4 drums, belt, 4 toners out and wipe 4 slits of glass because of a unplugged motor. I replaced the «Inner Left Duct» (pn= 302NR33020) which is the black plastic housing for the drive train for all 4 LSU cleaners. Don’t forget to grease those gears either. Fairly easy job after having to pull everything out a dozen times.

Code

4204

Laser output error (Yellow)

The pin photo signal (PDN) is not output

from PD PWB Y for one second while

laser is emitted.

4600

LSU cleaning motor error

When the LSU cleaning motor is driven,

the LSU cleaning motor over-current

detection signal is detected continu-

ously for 50 times (5 s) at 100 ms inter-

vals.

4700

VIDEO ASIC device error

Contents

Causes

Check procedures/corrective measures

Defective harness

Reinsert the connector. Also check for conti-

between APC

nuity within the connector harness. If none,

PWB Y and engine

remedy or replace the harness.

PWB (YC29), or

improper connec-

tor insertion.

Defective APC

Replace the laser scanner unit YK (See

PWB Y.

page 1-5-37).

Defective PD PWB

Replace the laser scanner unit YK (See

Y.

page 1-5-37).

Defective engine

Replace the engine PWB (See page 1-5-

PWB.

29).

Defective harness

Reinsert the connector. Also check for conti-

between LSU

nuity within the connector harness. If none,

cleaning motor and

remedy or replace the harness.

engine PWB

(YC37), or

improper connec-

tor insertion.

Defective drive

Check if the rollers and gears rotate

transmission sys-

smoothly. If not, grease the bushings and

tem of the LSU

gears. Check for broken gears and replace if

cleaning motor.

any.

Defective LSU

Replace the LSU cleaning motor.

cleaning motor.

Defective engine

Replace the engine PWB (See page 1-5-

PWB.

29).

Faulty connection

Check the installation of the main PWB and

of the connector

engine PWB and reinstall them if necessary

between the main

(See page 1-5-28 and 1-5-29).

PWB and engine

PWB.

Defective main

Replace the main PWB (See page 1-5-28).

PWB.

Defective engine

Replace the engine PWB (See page 1-5-

PWB.

29).

Remarks

2K8

1-4-11

Ошибка 4600

Ошибка блока лазера. Не работаетзаедает двигатель очистки лазера. Как правило из за пыли. Необходимо прочистить направляющие блока лазеров.

Разборка МФУ

- Отключаем МФУ от электросети

- Вынимаем лотки с бумагой

- Открываем крышку блока картриджей

- Выкручиваем винты из крышки слева

- Снимаем крышку

Блок лазеров

- Отсоединяем кабели

- Выкручиваем 4 винта крепления

- Вытаскиваем блок лазеров

Чистка блока лазеров

- Очищаем направляющие от пыли (продуть воздухом)

- Вставляем блок обратно

- Подключаем кабель, проверяем что бы все было плотно

- Подключаем электропитание, включаем МФУ и проверяем что все работает

- Собираем в обратном порядке

Похожие видео

Дополнительные материалы

Полная разборка TR-896A — блок переноса Kyocera FSC-8525/8520.Ч1Подробнее

Сборка блока TR-896A МФУ Kyocera FSC-8525/8520Подробнее

حل مشكلة كود الخطأ Call Service 4600 لطابعات وماكينات تصوير كيوسيراПодробнее

حل مشكلة كود الخطأ C4600 لماكينات تصوير كيوسيرا A3Подробнее

Некачественный совместимый тонер вывел из строя принтер Kyocera 8525Подробнее

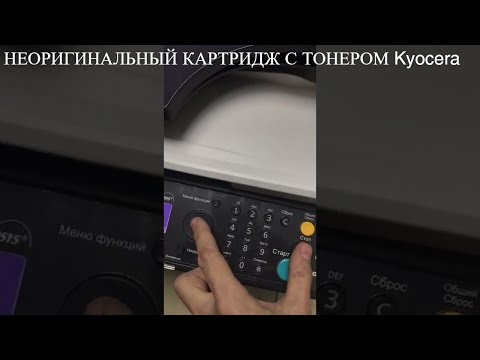

Ошибка Неоригинальный картридж с тонером Kyocera #ShortsПодробнее

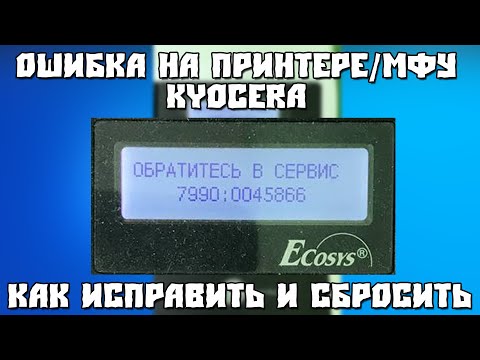

Принтер/МФУ Kyocera: Обратитесь в Сервис 7990 0045866Подробнее

Как убрать ошибку «Неоригинальный картридж с тонером» на KyoceraПодробнее

Что делать, если МФУ Kyocera не работает по сети в Windows 10Подробнее

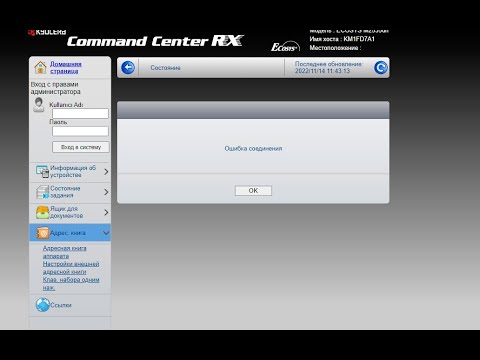

Ошибка соединения — при сканировании по сети на МФУ Kyocera / Connection error #Kyocera network scanПодробнее

How to upgrade firmware on Kyocera C8525MFPПодробнее

Сброс ошибки «Мало Тонера» на Kyocera ECOSYS 2335DПодробнее

Ошибка C 4000 в мфу Kyocera, типа fs-1120mfp/fs-1025mfp и т.п… Блок LSU.Подробнее