Модератор: vetal

dviz » Вт дек 30, 2014 2:15 pm

Последний раз редактировалось dviz Вт дек 30, 2014 2:15 pm, всего редактировалось 1 раз.

- За это сообщение автора dviz поблагодарил:

- S S S

-

dviz

- Эксперт по тонеру

-

- Персональный альбом

S S S » Вт дек 30, 2014 2:17 pm

dviz писал(а):Смотри механизм подъёма бумаги в лотке — сам лоток может заклинило или шестерни или движок.

совершенно верно, шестерня вылетела из пазов, благодарю!

при дальнейшем осмотре выяснилось ещё что сам механизм который подходит к шестерне сломан.

-

S S S

- Испачкался тонером

-

- ICQ

- Персональный альбом

-

-

Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

manik.76 в форуме Принтеры, МФУ, копиры формата A3

- 3

- 9650

dviz

Пн фев 20, 2017 1:35 pm

-

Taskalfa 180 ошибка «Е» и «Встряхните картр. с тонером»

-

-

«ошибка принтера HSYNC»

Sunat в форуме Xerox 3100 и иже с ним…

- 10

- 29011

Sunat

Сб май 10, 2014 6:19 am

-

«ошибка принтера HSYNC»

-

-

brother DCP 7030R «ошибка барабана»

vg2804 в форуме Принтеры, МФУ, факсы, копиры формата A4

- 14

- 19743

Rexvil

Пт окт 09, 2020 8:01 am

-

brother DCP 7030R «ошибка барабана»

-

-

Samsung SCX 4300 V 1.15. Ошибка «Нет картриджа»

PrintFree в форуме Картриджи, их заправка и дефекты.

- 9

- 10373

С.Н.Н.

Пт авг 19, 2011 7:16 pm

-

Samsung SCX 4300 V 1.15. Ошибка «Нет картриджа»

-

-

Canon mf635cx ошибка «замятие»

belocarsk в форуме Принтеры, МФУ, факсы, копиры формата A4

- 8

- 5232

belocarsk

Пн мар 04, 2019 12:23 pm

-

Canon mf635cx ошибка «замятие»

Вернуться в Принтеры, МФУ, факсы, копиры формата A4

Кто сейчас на форуме

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 78

-

12-07-2020

#1

Trusted Tech

50+ Posts

- Rep Power

- 16

Kyocera M3550 C1010 error

I have a customer with a Kyocera M3550 that is showing a C1010 error. I am planning on swapping out machine, due to the difficulty of this repair. However the customer does a lot of faxing, and had a number of faxes in memory due to the error. He did not have any forwarding set up so he does not have a copy of these and really needs them.

1. Does someone know if there is a way to forward faxes waiting to print in the job log? Or if this printer will print from a second cassette or MP tray with this error? Trying to gather some info before I go out.

thank you

-

12-07-2020

#2

Re: Kyocera M3550 C1010 error

the code is probably intermittent, it’ll work better with fewer sheets in the cassette (less weight)

or reboot to clear, keep the cassette out and load the bypass.

By the way you can fix your machine by using a CT3100 cassette

302MS93011

It’s spring loaded so it doesn’t use the machine lift drive.

-

12-07-2020

#3

Trusted Tech

50+ Posts

- Rep Power

- 16

Re: Kyocera M3550 C1010 error

Originally Posted by JR2ALTA

the code is probably intermittent, it’ll work better with fewer sheets in the cassette (less weight)

or reboot to clear, keep the cassette out and load the bypass.

By the way you can fix your machine by using a CT3100 cassette

302MS93011

It’s spring loaded so it doesn’t use the machine lift drive.

*********************************

Thank you!

Tags for this Thread

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

Ошибки Kyocera ECOSYS M2030dn

Ошибки Kyocera ECOSYS M2030pn

Ошибки Kyocera ECOSYS M2035dn

Ошибки Kyocera ECOSYS M2040dn

Ошибки Kyocera ECOSYS M2135dn

Ошибки Kyocera ECOSYS M2530dn

Ошибки Kyocera ECOSYS M2535dn

Ошибки Kyocera ECOSYS M2540dn

Ошибки Kyocera ECOSYS M2540dw

Ошибки Kyocera ECOSYS M2635dn

Ошибки Kyocera ECOSYS M2635dw

Ошибки Kyocera ECOSYS M2640idw

Ошибки Kyocera ECOSYS M3040dn

Ошибки Kyocera ECOSYS M3040idn

Ошибки Kyocera ECOSYS M3145dn

Ошибки Kyocera ECOSYS M3145idn

Ошибки Kyocera ECOSYS M2735dw

Ошибки Kyocera ECOSYS M3540dn

Ошибки Kyocera ECOSYS M3540idn

Ошибки Kyocera ECOSYS M3550idn

Ошибки Kyocera ECOSYS M3560idn

Ошибки Kyocera ECOSYS M3645dn

Ошибки Kyocera ECOSYS M3645idn

Ошибки Kyocera ECOSYS M3655idn

Ошибки Kyocera ECOSYS M3660idn

Ошибки Kyocera ECOSYS M3860idn

Ошибки Kyocera ECOSYS M3860idn

Ошибки Kyocera ECOSYS M4125idn

Ошибки Kyocera ECOSYS M4132idn

Ошибки Kyocera ECOSYS M5521cdn

Ошибки Kyocera ECOSYS M5521cdw

Ошибки Kyocera ECOSYS M5526cdn

Ошибки Kyocera ECOSYS M5526cdw

Ошибки Kyocera ECOSYS M6026cdn

Ошибки Kyocera ECOSYS M6026cidn

Ошибки Kyocera ECOSYS M6030cdn

Ошибки Kyocera ECOSYS M6035cidn

Ошибки Kyocera ECOSYS M6230cidn

Ошибки Kyocera ECOSYS M6235cidn

Ошибки Kyocera ECOSYS M6526cdn

Ошибки Kyocera ECOSYS M6526cidn

Ошибки Kyocera ECOSYS M6530cdn

Ошибки Kyocera ECOSYS M6535cidn

Ошибки Kyocera ECOSYS M6630cidn

Ошибки Kyocera ECOSYS M6635cidn

Ошибки Kyocera ECOSYS M8124cidn

Ошибки Kyocera ECOSYS M8130cidn

Ошибки Kyocera ECOSYS P2035d

Ошибки Kyocera ECOSYS P2040dn

Ошибки Kyocera ECOSYS P2040dw

Ошибки Kyocera ECOSYS P2135d

Ошибки Kyocera ECOSYS P2135dn

Ошибки Kyocera ECOSYS P2235dn

Ошибки Kyocera ECOSYS P2235dw

Ошибки Kyocera ECOSYS P3045dn

Ошибки Kyocera ECOSYS P3050dn

Ошибки Kyocera ECOSYS P3055dn

Ошибки Kyocera ECOSYS P3060dn

Ошибки Kyocera ECOSYS P3145dn

Ошибки Kyocera ECOSYS P3150dn

Ошибки Kyocera ECOSYS P3155dn

Ошибки Kyocera ECOSYS P3160dn

Ошибки Kyocera ECOSYS P3260dn

Ошибки Kyocera ECOSYS P4035dn

Ошибки Kyocera ECOSYS P4040dn

Ошибки Kyocera ECOSYS P5021cdn

Ошибки Kyocera ECOSYS P5021cdw

Ошибки Kyocera ECOSYS P5026cdn

Ошибки Kyocera ECOSYS P5026cdw

Ошибки Kyocera ECOSYS P6021cdn

Ошибки Kyocera ECOSYS P6026cdn

Ошибки Kyocera ECOSYS P6030cdn

Ошибки Kyocera ECOSYS P6035cdn

Ошибки Kyocera ECOSYS P6130cdn

Ошибки Kyocera ECOSYS P6230cdn

Ошибки Kyocera ECOSYS P6235cdn

Ошибки Kyocera ECOSYS P7035cdn

Ошибки Kyocera ECOSYS P7040cdn

Ошибки Kyocera ECOSYS P7240cdn

Ошибки Kyocera ECOSYS P8060cdn

Ошибки Kyocera FS-C8600DN

Ошибки Kyocera FS-C8650DN

Ошибки Kyocera FS1016MFP

Ошибки Kyocera FS1018MFP

Ошибки Kyocera FS1020MFP

Ошибки Kyocera FS1024MFP

Ошибки Kyocera FS1025MFP

Ошибки Kyocera FS1028MFP

Ошибки Kyocera FS1030MFP

Ошибки Kyocera FS1035MFP

Ошибки Kyocera FS1040

Ошибки Kyocera FS1050

Ошибки Kyocera FS1060DN

Ошибки Kyocera FS1100

Ошибки Kyocera FS1110

Ошибки Kyocera FS1116MFP

Ошибки Kyocera FS1118MFP

Ошибки Kyocera FS1120

Ошибки Kyocera FS1120MFP

Ошибки Kyocera FS1124MFP

Ошибки Kyocera FS1125MFP

Ошибки Kyocera FS1128MFP

Ошибки Kyocera FS1130MFP

Ошибки Kyocera FS1135MFP

Ошибки Kyocera FS1200

Ошибки Kyocera FS1220MFP

Ошибки Kyocera FS1300D

Ошибки Kyocera FS1320D

Ошибки Kyocera FS1320MFP

Ошибки Kyocera FS1325MFP

Ошибки Kyocera FS1350DN

Ошибки Kyocera FS1370DN

Ошибки Kyocera FS1500

Ошибки Kyocera FS6020

Ошибки Kyocera FS6025MFP

Ошибки Kyocera FS6025MFPB

Ошибки Kyocera FS6030MFP

Ошибки Kyocera FS6500

Ошибки Kyocera FS6525MFP

Ошибки Kyocera FS6530MFP

Ошибки Kyocera FS6700

Ошибки Kyocera FS6900

Ошибки Kyocera FS6950DN

Ошибки Kyocera FS8000CD

Ошибки Kyocera FS8000CN

Ошибки Kyocera FS8100DN

Ошибки Kyocera TASKalfa 180

Ошибки Kyocera TASKalfa 1800

Ошибки Kyocera TASKalfa 1801

Ошибки Kyocera TASKalfa 181

Ошибки Kyocera TASKalfa 205c

Ошибки Kyocera TASKalfa 220

Ошибки Kyocera TASKalfa 2200

Ошибки Kyocera TASKalfa 2201

Ошибки Kyocera TASKalfa 221

Ошибки Kyocera TASKalfa 2420w

Ошибки Kyocera TASKalfa 2460ci

Ошибки Kyocera TASKalfa 2470ci

Ошибки Kyocera TASKalfa 250ci

Ошибки Kyocera TASKalfa 2510i

Ошибки Kyocera TASKalfa 2520i

Ошибки Kyocera TASKalfa 255

Ошибки Kyocera TASKalfa 2550ci

Ошибки Kyocera TASKalfa 2551ci

Ошибки Kyocera TASKalfa 2552ci

Ошибки Kyocera TASKalfa 2553ci

Ошибки Kyocera TASKalfa 255b

Ошибки Kyocera TASKalfa 255c

Ошибки Kyocera TASKalfa 265ci

Ошибки Kyocera TASKalfa 300ci

Ошибки Kyocera TASKalfa 300i

Ошибки Kyocera TASKalfa 3010i

Ошибки Kyocera TASKalfa 3011i

Ошибки Kyocera TASKalfa 305

Ошибки Kyocera TASKalfa 3050ci

Ошибки Kyocera TASKalfa 3051ci

Ошибки Kyocera TASKalfa 306ci

Ошибки Kyocera TASKalfa 307ci

Ошибки Kyocera TASKalfa 308ci

Ошибки Kyocera TASKalfa 3212i

Ошибки Kyocera TASKalfa 3252ci

Ошибки Kyocera TASKalfa 3253ci

Ошибки Kyocera TASKalfa 3500i

Ошибки Kyocera TASKalfa 3501i

Ошибки Kyocera TASKalfa 350ci

Ошибки Kyocera TASKalfa 3510i

Ошибки Kyocera TASKalfa 3511i

Ошибки Kyocera TASKalfa 3550ci

Ошибки Kyocera TASKalfa 3551ci

Ошибки Kyocera TASKalfa 3552ci

Ошибки Kyocera TASKalfa 3553ci

Ошибки Kyocera TASKalfa 356ci

Ошибки Kyocera TASKalfa 358ci

Ошибки Kyocera TASKalfa 4002i

Ошибки Kyocera TASKalfa 4003i

Ошибки Kyocera TASKalfa 400ci

Ошибки Kyocera TASKalfa 4012i

Ошибки Kyocera TASKalfa 4052ci

Ошибки Kyocera TASKalfa 4053ci

Ошибки Kyocera TASKalfa 406ci

Ошибки Kyocera TASKalfa 408ci

Ошибки Kyocera TASKalfa 420i

Ошибки Kyocera TASKalfa 4500i

Ошибки Kyocera TASKalfa 4501i

Ошибки Kyocera TASKalfa 4550ci

Ошибки Kyocera TASKalfa 4551ci

Ошибки Kyocera TASKalfa 4820w

Ошибки Kyocera TASKalfa 5002i

Ошибки Kyocera TASKalfa 5003i

Ошибки Kyocera TASKalfa 500ci

Ошибки Kyocera TASKalfa 5052ci

Ошибки Kyocera TASKalfa 5053ci

Ошибки Kyocera TASKalfa 508ci

Ошибки Kyocera TASKalfa 520i

Ошибки Kyocera TASKalfa 5500i

Ошибки Kyocera TASKalfa 5501i

Ошибки Kyocera TASKalfa 550c

Ошибки Kyocera TASKalfa 552ci

Ошибки Kyocera TASKalfa 5550ci

Ошибки Kyocera TASKalfa 5551ci

Ошибки Kyocera TASKalfa 6002i

Ошибки Kyocera TASKalfa 6003i

Ошибки Kyocera TASKalfa 6052ci

Ошибки Kyocera TASKalfa 6053ci

Ошибки Kyocera TASKalfa 620

Ошибки Kyocera TASKalfa 6500i

Ошибки Kyocera TASKalfa 6501i

Ошибки Kyocera TASKalfa 650c

Ошибки Kyocera TASKalfa 6550ci

Ошибки Kyocera TASKalfa 6551ci

Ошибки Kyocera TASKalfa 7002i

Ошибки Kyocera TASKalfa 7003i

Ошибки Kyocera TASKalfa 7052ci

Ошибки Kyocera TASKalfa 7353ci

Ошибки Kyocera TASKalfa 750c

Ошибки Kyocera TASKalfa 7550ci

Ошибки Kyocera TASKalfa 7551ci

Ошибки Kyocera TASKalfa 8000i

Ошибки Kyocera TASKalfa 8001i

Ошибки Kyocera TASKalfa 8002i

Ошибки Kyocera TASKalfa 8003i

Ошибки Kyocera TASKalfa 8052ci

Ошибки Kyocera TASKalfa 820

Ошибки Kyocera TASKalfa 8353ci

Ошибки Kyocera TASKalfa 9002i

Ошибки Kyocera TASKalfa 9003i

- Code: C0030

- Description: Fax control PWB system problem

Processing with the fax software was disabled due to a hardware or software problem. - Causes: Defective fax control PWB.

- Remedy: Replace the fax control PWB and verify the operation.

- Code: C0060

- Description: Main PWB type mismatch error

- Causes: Defective PWB.

- Remedy: Run maintenance item U935 to contact the Service Administrative Division.

- Code: C0070

- Description: Abnormal detection of fax control PWB incompatibility

In the initial communication with the fax control PWB, any normal communication command is not transmitted. - Causes: Defective fax software.

Defective fax control PWB. - Remedy: Defective fax software. Install the fax software.

Defective fax control PWB. Replace the fax control PWB and verify the operation.

- Code: C0100

- Description: Backup memory (EEPROM) device problem (Main PWB)

Reading from or writing to EEPROM cannot be performed. - Causes: Defective main PWB.

Device damage of EEPROM. - Remedy: Defective main PWB. Replace the main PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: C0120

- Description: MAC address data error

For data in which the MAC address is invalid. - Causes: Defective main PWB.

- Remedy: Replace the main PWB and check for correct operation.

- Code: C0150

- Description: Backup memory (EEPROM) device problem (Engine PWB)

Reading from or writing to EEPROM cannot be performed. - Causes: Defective engine PWB.

Device damage of EEPROM. - Remedy: Defective engine PWB. Replace the engine PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: C0160

- Description: Backup memory (EEPROM) data problem (Engine PWB)

Reading data from EEPROM is abnormal. Read and write data does not match 5 times continuously. - Causes: Data damage of EEPROM.

- Remedy: Contact the Service Administrative Division.

- Code: C0170

- Description: Copy counts problem

A checksum error is detected in the main and engine backup memories for the copy counters. - Causes: Data damage of EEPROM.

Defective PWB. - Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

Defective PWB. Replace the main PWB or engine PWB and check for correct operation.

- Code: C0180

- Description: Machine number mismatch error

Machine number of main PWB and engine PWB does not match. - Causes: Data damage of EEPROM.

- Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

- Code: C0620

- Description: FAX image DIMM problem

DIMM is not installed correctly. DIMM cannot be accessed. - Causes: DIMM installed incorrectly.

Defective main PWB. - Remedy: DIMM installed incorrectly. Check if the DIMM is inserted into the socket on the main PWB correctly.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0630

- Description: DMA problem

DMA transmission of image data does not complete within the specified period of time. - Causes: Poor contact in the connector terminals.

Defective main PWB. - Remedy: Poor contact in the connector terminals. Check the connection the signal cable for CIS and the main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0640

- Description: Hard disk drive problem

The hard disk cannot be accessed. - Causes: Poor contact in the connector terminals.

Defective hard disk.

Defective main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC49 on the main PWB and the connector on the hard disk. Repair or replace if necessary.

Defective hard disk. Run U024 (HDD formatting) without turning the power off to initialize the hard disk. Replace the hard disk drive and check for correct operation if the problem is still detected after initialization.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0650

- Description: FAX image DIMM check problem

Improper DIMM is installed. - Causes: DIMM installed incorrectly.

DIMM of another machine is installed.

Defective main PWB. - Remedy: DIMM installed incorrectly. Check if the DIMM is inserted into the socket on the main PWB correctly.

DIMM of another machine is installed. Perform maintenance mode U671 (RECOVERY FAX DIMM).

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0800

- Description: Image processing problem

JAM05 is detected twice. - Causes: Defective main PWB.

- Remedy: Defective main PWB. Replace the main PWB and check for correct operation.

- Code: C0830

- Description: Fax control PWB flash program area checksum error

A checksum error occurred with the program of the fax control PWB. - Causes: Defective fax software.

Defective fax control PWB. - Remedy: Defective fax software. Install the fax software.

Defective fax control PWB. Replace the fax control PWB and verify the operation.

- Code: C0840

- Description: Faults of RTC

The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. - Causes: Defective main PWB.

The battery is disconnected from the main PWB. - Remedy: Defective main PWB. Replace the main PWB and check for correct operation.

The battery is disconnected from the main PWB. Check visually and remedy if necessary.

- Code: C0870

- Description: Fax control PWB to main PWB high capacity data transfer problem

High-capacity data transfer between the fax control PWB and the scanner MIP PWB was not normally performed even if the data transfer was retried 10 times. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the interface PWB and the connector on the fax control PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the fax control PWB or main PWB and check for correct operation.

- Code: C0920

- Description: Fax file system error

The backup data is not retained for file system abnormality of flash memory of the fax control PWB. - Causes: Defective fax control PWB.

- Remedy: Defective fax control PWB. Replace the fax control PWB and verify the operation.

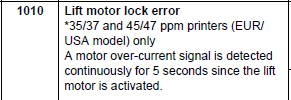

- Code: C1010

- Description: Lift motor 1 error

After cassette 1 is inserted, lift switch 1 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals.

Broken gears or couplings of lift motor 1.

Defective lift motor 1.

Poor contact in the connector terminals.

Defective lift switch 1.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector of lift motor 1 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of lift motor 1. Replace lift motor 1.

Defective lift motor 1. Check for continuity across the coil. If none, replace lift motor 1.

Poor contact in the connector terminals. Check the connection of connector of lift switch 1 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective lift switch 1. Check if YC8-B9 on the engine PWB goes low when lift switch 1 is turned off. If not, replace lift switch 1.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C1020

- Description: Lift motor 2 error

After cassette 2 is inserted, lift switch 2 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals.

Broken gears or couplings of lift motor 2.

Defective lift motor 2.

Poor contact in the connector terminals.

Defective lift switch 2.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector of lift motor 2 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of lift motor 2. Replace lift motor 2.

Defective lift motor 2. Check for continuity across the coil. If none, replace lift motor 2.

Poor contact in the connector terminals. Check the connection of connector of lift switch 2 and the connector YC8 on the engine PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective lift switch 2. Check if YC8-B15 on the engine PWB goes low when lift switch 2 is turned off. If not, replace lift switch 2.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C1030

- Description: PF lift motor 1 error (optional paper feeder)

After cassette 3 is inserted, PF lift switch 1 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals.

Broken gears or couplings of PF lift motor 1.

Defective PF lift motor 1.

Defective PF lift switch 1. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of PF lift motor 1. Replace PF lift motor 1.

Defective PF lift motor 1. Check for continuity across the coil. If none, replace PF lift motor 1.

Defective PF lift switch 1. Check if YC1-7 on the PF main PWB goes low when PF lift switch 1 is turned off. If not, replace PF lift switch 1.

- Code: C1040

- Description: PF lift motor 2 error (optional paper feeder)

After cassette 4 is inserted, PF lift switch 2 does not turn on within 12 s. This error is detected four times successively. - Causes: Poor contact in the connector terminals

Broken gears or couplings of PF lift motor 2.

Defective PF lift motor 2.

Defective PF lift switch 2. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Broken gears or couplings of PF lift motor 2. Replace PF lift motor 2.

Defective PF lift motor 2. Check for continuity across the coil. If none, replace PF lift motor 2.

Defective PF lift switch 2. Check if YC1-9 on the PF main PWB goes low when PF lift switch 2 is turned off. If not, replace PF lift switch 2.

- Code: C1100

- Description: PF lift motor 1 error (optional 3000sheet paper feeder)

A motor over-current signal is detected continuously for 1 s or longer. - Causes: Poor contact in the connector terminals.

PF lift motor 1 does not rotate correctly (the motor is overloaded). - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

PF lift motor 1 does not rotate correctly (the motor is overloaded). Check the gears and remedy if necessary.

- Code: C1110

- Description: PF lift motor 2 error (optional 3000sheet paper feeder)

A motor over-current signal is detected continuously for 1 s or longer. - Causes: Poor contact in the connector terminals.

PF lift motor 2 does not rotate correctly (the motor is overloaded). - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

PF lift motor 2 does not rotate correctly (the motor is overloaded). Check the gears and remedy if necessary.

- Code: C1120

- Description: PF left lift position problem (optional 3000-sheet paper feeder)

Level switch 1 does not turn on within 30 s of PF lift motor 1 turning on. - Causes: Poor contact in the connector terminals.

Defective level switch 1.

Defective PF lift motor 1.

The PF left lift does not rise properly. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective level switch 1. Check if YC5-4 on the PF main PWB goes low when level switch 1 is turned off. If not, replace level switch 1.

Defective PF lift motor 1. Check for continuity across the coil. If none, replace PF lift motor 1.

The PF left lift does not rise properly. Check the gears and belts, and remedy if necessary.

- Code: C1130

- Description: PF right lift position problem (optional 3000-sheet paper feeder)

Level switch 2 does not turn on within 30 s of PF lift motor 2 turning on. - Causes: Poor contact in the connector terminals.

Defective level switch 2.

Defective PF lift motor 2.

The PF right lift does not rise properly. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective level switch 2. Check if YC5-7 on the PF main PWB goes low when level switch 2 is turned off. If not, replace level switch 2.

Defective PF lift motor 2. Check for continuity across the coil. If none, replace PF lift motor 2.

The PF right lift does not rise properly. Check the gears and belts, and remedy if necessary.

- Code: C1800

- Description: Paper feeder communication error (optional paper feeder)

A communication error from paper feeder is detected 10 times in succession. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the PF main PWB or engine PWB and check for correct operation.

- Code: C1900

- Description: Paper feeder EEPROM error (optional paper feeder)

When writing the data, the write data and the read data is not continuously in agreement three times. - Causes: Poor contact in the connector terminals.

Defective engine PWB.

Defective paper feeder. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective paper feeder. Replace the paper feeder with another unit and check the operation. If the operation is normal, replace or repair optional paper feeder.

- Code: C2000

- Description: Drive motor problem

Stable OFF is detected for 1 s continuously after drive motor stability. The drive motor is not stabilized in 6 s since the motor is activated. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective drive motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC11 on the engine PWB and the connector on the drive motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective drive motor. Replace the drive motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C2250

- Description: Main charger cleaning motor error

A locking error has been detected three times in a row during a reciprocating cleaning motion. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective main charger cleaning motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the engine PWB and the connector on the main charger cleaning motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective main charger cleaning motor. Replace the main charger cleaning motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C2500

- Description: Paper feed motor error

Stable OFF is detected for 1 s continuously after paper feed motor stability. The paper feed motor is not stabilized in 6 s since the motor is activated. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective paper feed motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC11 on the engine PWB and the connector on the paper feed motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective paper feed motor. Replace the paper feed motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C2600

- Description: PF paper conveying/drive motor error (optional 3000-sheet paper feeder/ paper feeder)

The lock signal of the motor is detected above 450 ms. - Causes: Poor contact in the connector terminals.

Defective drive transmission system.

Defective PF paper conveying/drive motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC15 on the engine PWB and the connector on the PF main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective drive transmission system. Check if the rollers and gears rotate smoothly. If not, grease the bushings and gears. Check for broken gears and replace if any.

Defective PF paper conveying/drive motor. Replace the PF paper conveying/drive motor.

Defective PWB. Replace the PF main PWB or engine PWB and check for correct operation.

- Code: C3100

- Description: Scanner carriage problem

The home position is not correct when the power is turned on or at the start of copying using the table. - Causes: Poor contact in the connector terminals.

Defective home position switch.

Defective scanner motor.

The mirror frame, exposure lamp, or scanner wire is defective.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC8 on the ISM PWB and the connector of the home position switch, and the connection of connector YC7 on the ISM PWB and the connector on the scanner motor and the continuity across the connector terminals. Repair or replace if necessary.

Defective home position switch. Replace the scanner home position switch.

Defective scanner motor. Replace the scanner motor.

The mirror frame, exposure lamp, or scanner wire is defective. Check if the mirror flames and exposure lamp are on the rail. And check the scanner wire winds correctly.

Defective PWB. Replace the ISM PWB or ISC PWB and check for correct operation.

- Code: C3200

- Description: Exposure lamp problem

When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s. - Causes: Poor contact in the connector terminals.

Defective exposure lamp.

Incorrect shading position.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the ISM PWB and the connector on the inverter PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective exposure lamp or inverter PWB. Replace the exposure lamp or inverter PWB.

Incorrect shading position. Adjust the position of the contact glass (shading plate). If the problem still occurs, replace the scanner home position switch.

Defective PWB. Replace the ISM PWB, ISC PWB or CCD PWB and check for correct operation.

- Code: C3210

- Description: CIS lamp problem

When input value at the time of CIS illumination does not exceed the threshold value between 5 s. - Causes: Poor contact in the connector terminals.

Defective DP driver PWB.

Defective DP inverter PWB.

Defective CIS. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the ISM PWB and the connector on the DP driver PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective DP driver PWB. Replace the DP driver PWB and check for correct operation.

Defective DP inverter PWB. Replace the DP inverter PWB and check for correct operation.

Defective CIS. Replace the CIS and check for correct operation.

- Code: C3300

- Description: Optical system (AGC) problem

After AGC, correct input is not obtained at CCD. - Causes: Poor contact in the connector terminals.

Defective exposure lamp or inverter PWB.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the ISM PWB and the connector on the inverter PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective exposure lamp or inverter PWB. Replace the exposure lamp or inverter PWB.

Defective PWB. Replace the ISM PWB, ISC PWB or CCD PWB and check for correct operation.

- Code: C3310

- Description: CIS AGC problem

After AGC, correct input is not obtained at CIS. - Causes: Defective DP driver PWB.

CIS output problem.

Defective DP inverter PWB. - Remedy: Defective DP driver PWB. Replace the DP driver PWB and check for correct operation.

CIS output problem. Replace the CIS and check for correct operation.

Defective DP inverter PWB. Replace the DP inverter PWB and check for correct operation.

- Code: C3500

- Description: Communication error between scanner and SHD

An error code is detected. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC2 on the CCD PWB and the connector YC2 on the ISC PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the CCD PWB or ISC PWB and check for correct operation.

- Code: C3900

- Description: Backup memory read/write problem (ISC PWB)

Read and write data does not match. - Causes: Defective backup RAM or PWB.

- Remedy: Replace the ISC PWB or ISM PWB and check for correct operation.

- Code: C3910

- Description: Backup memory data problem (ISC PWB)

Data in the specified area of the backup memory does not match the specified values. - Causes: Defective backup RAM or PWB.

- Remedy: Replace the ISC PWB or ISM PWB and check for correct operation.

- Code: C4000

- Description: Polygon motor synchronization problem

The polygon motor does not reach the stable speed within 20 s of the START signal turning on. - Causes: Poor contact in the connector terminals.

Defective polygon motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC3 on the engine PWB and laser scanner unit, and the continuity across the connector terminals. Repair or replace if necessary.

Defective polygon motor. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C4010

- Description: Polygon motor steady-state problem

Stable OFF is detected for 20 s continuously after polygon motor stability. - Causes: Poor contact in the connector terminals.

Defective polygon motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC3 on the engine PWB and laser scanner unit, and the continuity across the connector terminals. Repair or replace if necessary.

Defective polygon motor. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C4100

- Description: BD initialization problem

5 consecutive BD errors were detected during an 800 ms interval after the polygon motor stabilized. - Causes: Poor contact in the connector terminals.

Defective polygon motor.

Defective engine PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC3 on the engine PWB and laser scanner unit, and the continuity across the connector terminals. Repair or replace if necessary.

Defective polygon motor. Replace the laser scanner unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6000

- Description: Fuser heater break

Fuser thermistor 1 detected less than 70°C/158°F for 10 s during warm-up and ready in. During warm-up, the temperature at the fuser unit thermistor 1 does not rise by 1°C/1.8°F continuously for 5 s. Fuser thermistor 2 detected less than 40°C/104°F for 10 s during warm-up and ready in. During warm-up, the temperature at the fuser unit thermistor 2 does not rise by 1°C/1.8°F continuously for 5 s. - Causes: Defective fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1.

Defective fuser thermostat.

Defective PWB. - Remedy: Defective fuser heater 1 or 2. Replace the fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1. Check the mounting state of the fuser thermistor 1. If any problem is found, repair it.

Defective fuser thermostat. Replace the fuser thermostat.

Defective PWB. Replace the power source PWB or engine PWB and check for correct operation.

- Code: C6020

- Description: Abnormally high fuser thermistor temperature

Fuser thermistor 1 or 2 is detected 250°C/482°F or more for 40 ms. - Causes: Installation defectiveness on fuser thermistor 1 or 2.

Defective fuser thermistor unit 1 or 2.

Defective engine PWB. - Remedy: Installation defectiveness on fuser thermistor 1 or 2. Check the mounting state of the fuser thermistor 1 or 2. If any problem is found, repair it.

Defective fuser thermistor unit 1 or 2. Replace the fuser thermistor 1 or 2.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6030

- Description: Fuser thermistor break error

The fuser thermistor break signal is detected continuously for 1 s. - Causes: Installation defectiveness on fuser thermistor 1 or 2.

Defective fuser thermistor 1 or 2.

Defective engine PWB. - Remedy: Installation defectiveness on fuser thermistor 1 or 2. Check the mounting state of the fuser thermistor 1 or 2. If any problem is found, repair it.

Defective fuser thermistor 1 or 2. Replace the fuser thermistor 1 or 2.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6040

- Description: Fuser thermistor 1 detection error

Fuser thermistor 1 detected an abnormal value for at least 1 s. - Causes: Installation defectiveness on fuser thermistor 1.

Defective fuser thermistor 1.

Defective engine PWB. - Remedy: Installation defectiveness on fuser thermistor 1. Check the mounting state of the fuser thermistor 1. If any problem is found, repair it.

Defective fuser thermistor 1. Replace the fuser thermistor 1.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: C6050

- Description: Abnormally low fuser thermistor temperature

Fuser thermistor 1 is detected 80°C/ 176°F less than 1 s continuously during copying. - Causes: Defective fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1.

Defective PWB. - Remedy: Defective fuser heater 1 or 2. Replace the fuser heater 1 or 2.

Installation defectiveness on fuser thermistor 1. Check the mounting state of the fuser thermistor 1. If any problem is found, repair it.

Defective PWB. Replace the power source PWB or engine PWB and check for correct operation.

- Code: C6400

- Description: Zero-cross signal error

While fuser heater ON/OFF control is performed, the zero-cross signal is not input within 3 s. - Causes: Defective PWB

- Remedy: Replace the power source PWB or engine PWB and check for correct operation.

- Code: C6410

- Description: Fuser unit connector insertion problem

Absence of the fuser unit is detected. - Causes: Fuser unit connector inserted incorrectly.

Defective fuser unit connector. - Remedy: Fuser unit connector inserted incorrectly. Reinsert the fuser unit connector if necessary.

Defective fuser unit connector. Replace the fuser unit.

- Code: C7300

- Description: Toner container problem

Toner level is not detected when toner empty is detected. - Causes: Poor contact in the connector terminals.

Defective toner container sensor. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective toner container sensor. Replace the toner container sensor.

- Code: C7400

- Description: Developing unit connector insertion problem Absence of the developing unit is detected.

- Causes: Developing unit connector inserted incorrectly.

Defective developing unit connector. - Remedy: Developing unit connector inserted incorrectly. Reinsert the developing unit connector if necessary.

Defective developing unit connector. Replace the developing unit.

- Code: C7410

- Description: Drum unit connector insertion problem

Absence of the drum unit is detected. - Causes: Drum unit connector inserted incorrectly.

Defective drum unit connector. - Remedy: Drum unit connector inserted incorrectly. Reinsert the drum unit connector if necessary.

Defective drum unit connector. Replace the drum unit.

- Code: C7800

- Description: Broken external thermistor wire

The thermistor output value is 4.5 V or more. - Causes: Poor contact in the connector terminals.

Defective humidity sensor. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC10 on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective humidity sensor. Replace the humidity sensor.

- Code: C7900

- Description: Drum EEPROM error

Reading from or writing to EEPROM cannot be performed. - Causes: Poor contact in the connector terminals.

Defective drum unit. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective drum unit. Replace the drum unit.

- Code: C7910

- Description: Developing unit EEPROM error

Reading from or writing to EEPROM cannot be performed. - Causes: Poor contact in the connector terminals.

Defective developing unit. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the engine PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective developing unit. Replace the developing unit.

- Code: C8020

- Description: Punch motor problem (optional 3000sheet document finisher)

The error signal of the punch motor is detected for more than 500 ms while the punch motor is operating. - Causes: Poor contact in the connector terminals.

Defective punch motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the punch PWB and the continuity across the connector terminals. Repair or replace if necessary.

Defective punch motor. Replace the punch motor.

Defective PWB. Replace the punch PWB or finisher main PWB and check for correct operation.

- Code: C8030

- Description: Tray upper limit detection problem (optional document finisher)

When the tray elevation motor raises a tray, the ON status of the tray upper limit sensor is detected. - Causes: The tray upper limit sensor, paper surface sensor 1/2 connector makes poor contact.

Defective tray upper limit sensor, paper surface sensor 1/2.

Defective finisher main PWB. - Remedy: The tray upper limit sensor, paper surface sensor 1/2 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective tray upper limit sensor, paper surface sensor 1/2. Replace the sensor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8040

- Description: Belt problem (optional document finisher)

The belt sensor does not turn on/off within specified time of the belt solenoid turning on. - Causes: The belt sensor, belt solenoid connector makes poor contact.

Defective belt sensor.

Defective belt solenoid.

Defective finisher main PWB. - Remedy: The belt sensor, belt solenoid connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective belt sensor. Replace the belt sensor.

Defective belt solenoid. Replace the belt solenoid.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8050

- Description: Paper conveying belt motor 1 problem (optional 3000-sheet document finisher)

Paper conveying belt home position sensor 1 does not turn off within 1.5 s. Paper conveying belt home position sensor 1 does not turn on within 2.5 s. Jam 88 is indicated. - Causes: Poor contact in the connector terminals.

Defective paper conveying belt home position sensor 1.

Defective paper conveying belt motor 1.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC2 on the inner tray PWB and the connector on paper conveying belt motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective paper conveying belt home position sensor 1. Replace paper conveying belt home position sensor 1.

Defective paper conveying belt motor 1. Replace paper conveying belt motor 1.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

- Code: C8060

- Description: Paper conveying belt motor 2 problem (optional 3000-sheet document finisher)

Paper conveying belt home position sensor 2 does not turn off within 1.5 s. Paper conveying belt home position sensor 2 does not turn on within 1.5 s. - Causes: Poor contact in the connector terminals.

Defective paper conveying belt home position sensor 2.

Defective paper conveying belt motor 2.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6 on the inner tray PWB and the connector on paper conveying belt motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective paper conveying belt home position sensor 2. Replace paper conveying belt home position sensor 2.

Defective paper conveying belt motor 2. Replace paper conveying belt motor 2.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

- Code: C8070

- Description: Inner tray communication error (optional 3000-sheet document finisher)

Communication with the inner tray is not possible although the connection is detected. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6 and YC24 on the finisher main PWB and the connector YC1 and YC4 on the inner tray PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

- Code: C8140

- Description: Main tray problem (optional 3000sheet document finisher)

The main tray is not detected by the main tray upper limit detection sensor or the main tray paper upper surface detection sensor within 20 s since the tray has started ascending. The main tray upper limit detection sensor or the main tray paper upper surface detection

Tray elevation motor problem (optional document finisher) The tray low limit sensor or paper surface sensor 1/2 cannot be detected to be on within 10 s since the tray elevation motor is activated. - Causes: Poor contact in the connector terminals.

Defective main tray motor.

Defective main tray

Defective finisher main PWB.

The tray elevation motor connector makes poor contact.

The tray elevation motor malfunctions.

The tray lower limit sensor, paper surface sensor 1/2 connector makes poor contact.

Defective tray lower limit sensor, paper surface sensor 1/2.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC11 on the finisher main PWB and the connector on the main tray motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective main tray motor. Replace the main tray motor.

Defective main tray upper limit detection sensor/main tray paper upper surface detection sensor/main tray lower limit detection sensor. Replace the sensor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

The tray elevation motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

The tray elevation motor malfunctions. Replace the tray elevation motor.

The tray lower limit sensor, paper surface sensor 1/2 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective tray lower limit sensor, paper surface sensor 1/2. Replace the sensor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8170

- Description: Side registration motor 1 problem (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 3 s passed. Jam 88 is indicated.

Finisher front side registration motor problem (optional built-in finisher) When the front-side registration home-position sensor is turned on during initialization, the sensor did not turn on while it has moved by 106 pulses. When the front-side registration home-position sensor is turned off during initialization, the sensor did not turn on in 3 s. - Causes: Poor contact in the connector terminals.

Defective side registration motor 1.

Defective PWB.

The front side registration motor connector makes poor contact.

Defective front side registration motor.

The front side registration home position sensor connector makes poor contact.

Defective front side registration home position sensor.

Defective finisher control PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC2 on the inner tray PWB and the connector on side registration motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective side registration motor 1. Replace side registration motor 1.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

The front side registration motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective front side registration motor. Replace front side registration motor.

The front side registration home position sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective front side registration home position sensor. Replace the front side registration home position sensor.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8180

- Description: Side registration motor 2 problem (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 3 s passed. Jam 88 is indicated.

Finisher rear side registration motor problem (optional built-in finisher) When the rear-side registration home-position sensor is turned on during initialization, the sensor did not turn on while it has moved by 106 pulses. When the rear-side registration home-position sensor is turned off during initialization, the sensor did not turn on in 3 s. - Causes: Poor contact in the connector terminals.

Defective side registration motor 2.

Defective PWB.

The rear side registration motor connector makes poor contact.

Defective rear side registration motor.

The rear side registration home position sensor connector makes poor contact.

Defective rear side registration home position sensor.

Defective finisher control PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC8 on the inner tray PWB and the connector of side registration motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective side registration motor 2. Replace side registration motor 2.

Defective PWB. Replace the inner tray PWB or finisher main PWB and check for correct operation.

The rear side registration motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective rear side registration motor. Replace rear side registration motor.

The rear side registration home position sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective rear side registration home position sensor. Replace the rear side registration home position sensor.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8190

- Description: Finisher trailing edge registration motor problem (optional built-in finisher)

When the trailing edge registration home-position sensor is turned on during initialization, the sensor did not turn on while it has moved by 106 pulses. When the trailing edge registration home-position sensor is turned off during initialization, the sensor did not turn on in 3 s. - Causes: The trailing edge registration motor connector makes poor contact.

Defective trailing edge registration motor.

The trailing edge registration home position sensor connector makes poor contact.

Defective trailing edge registration home position sensor.

Defective finisher control PWB. - Remedy: The trailing edge registration motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective trailing edge registration motor. Replace trailing edge registration motor.

The trailing edge registration home position sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective trailing edge registration home position sensor. Replace the trailing edge registration home position sensor.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8210

- Description: Stapler moving motor 1 error (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 1.5 s passed.

Stapler problem (optional document finisher) Jam 82 is indicated.

Finisher stapler problem (optional built-in finisher) The stapler home position sensor does not change state from nondetection to detection within 200 ms of the start of stapler motor counterclockwise (forward) rotation. During initialization, the stapler home position sensor does not change state from non-detection to detection within 600 ms of the start of stapler motor clockwise (reverse) rotation. - Causes: Poor contact in the connector terminals.

Defective stapler moving motor 1.

Defective finisher main PWB.

The stapler connector makes poor contact.

The stapler is blocked with a staple.

The stapler is broken.

Defective finisher main PWB.

The stapler connector makes poor contact.

The stapler is blocked with a staple.

The stapler is broken.

Defective finisher control PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC9 on the finisher main PWB and the connector of stapler moving motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective stapler moving motor 1. Replace stapler moving motor 1.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

The stapler connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

The stapler is blocked with a staple. Remove the stapler cartridge, and check the cartridge and the stapling section of the stapler.

The stapler is broken. Replace the stapler and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

The stapler connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

The stapler is blocked with a staple. Remove the stapler cartridge, and check the cartridge and the stapling section of the stapler.

The stapler is broken. Replace the front stapler and check for correct operation.

Defective finisher control PWB. Replace the finisher control PWB and check for correct operation.

- Code: C8220

- Description: Stapler moving motor 2 error (optional 3000-sheet document finisher)

When operation returned to a home position is performed at the time of initial operation and a home position is not detected even if 3.5 s passed. - Causes: Poor contact in the connector terminals.

Defective stapler moving motor 2.

Defective staple relay PWB.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC10 on the finisher main PWB and the connector of staple relay PWB and stapler moving motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective stapler moving motor 2. Replace stapler moving motor 2.

Defective staple relay PWB. Replace the staple relay PWB and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8230

- Description: Stapler motor problem (optional 3000sheet document finisher)

Jam 82 is indicated. - Causes: Poor contact in the connector terminals.

Defective stapler motor.

Defective staple relay PWB.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC10 on the finisher main PWB and the connector of staple relay PWB and stapler motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective stapler motor. Replace the stapler motor.

Defective staple relay PWB. Replace the staple relay PWB and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8300

- Description: Center-folding unit communication error (optional center-folding unit of 3000-sheet document finisher)

Communication with the center-folding unit is not possible although the connection is detected. - Causes: Poor contact in the connector terminals.

Defective centerfold set switch.

Defective centerfold main PWB.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 and YC20 on the finisher main PWB and the connector YC1 and YC2 on the centerfold main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold set switch. Replace the centerfold set switch.

Defective centerfold main PWB. Replace the centerfold main PWB and check for correct operation.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8310

- Description: Centerfold side registration motor 2 problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 1 s passed. - Causes: Poor contact in the connector terminals.

Defective centerfold side registration motor 2.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6 on the centerfold main PWB and the connector of centerfold side registration motor 2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold side registration motor 2. Replace centerfold side registration motor 2.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

- Code: C8320

- Description: Centerfold paper conveying belt motor problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 2.5 s passed.

Adjustment motor 2 problem (optional document finisher) The adjustment sensor 2 does not turn on/off within specified time of the adjustment motor 2 turning on. - Causes: Poor contact in the connector terminals.

Defective centerfold paper conveying belt motor 1/2.

Defective PWB.

The adjustment sensor 2, adjustment motor 2 connector makes poor contact.

Defective adjustment sensor 2.

Defective adjustment motor 2.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6, YC7 on the centerfold main PWB and the connector of centerfold paper conveying belt motor 1/2, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold paper conveying belt motor 1/2. Replace centerfold paper conveying belt motor 1/2.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The adjustment sensor 2, adjustment motor 2 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective adjustment sensor 2. Replace the adjustment sensor 2.

Defective adjustment motor 2. Replace the adjustment motor 2.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8330

- Description: Blade motor problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 1.5 s passed.

Adjustment motor 1 problem (optional document finisher) The adjustment sensor 1 does not turn on/off within specified time of the adjustment motor 1 turning on. - Causes: Poor contact in the connector terminals.

Defective blade motor.

Defective PWB.

The adjustment sensor 1, adjustment motor 1 connector makes poor contact.

Defective adjustment sensor 1.

Defective adjustment motor 1.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC8 on the centerfold main PWB and the connector of the blade motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective blade motor. Replace the blade motor.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The adjustment sensor 1, adjustment motor 1 connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective adjustment sensor 1. Replace the adjustment sensor 1.

Defective adjustment motor 1. Replace the adjustment motor 1.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8340

- Description: Centerfold staple motor problem (optional center-folding unit of 3000sheet document finisher)

Jam 89 is indicated. - Causes: Poor contact in the connector terminals.

Defective centerfold staple motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC9 on the centerfold main PWB and the connector of the centerfold staple motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold staple motor. Replace the centerfold staple motor.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

- Code: C8350

- Description: Centerfold side registration motor 1 problem (optional center-folding unit of 3000-sheet document finisher)

The home position is not detected when initial operation even if 1 s passed.

Roller motor problem (optional document finisher) The roller sensor does not turn on/off within specified time of the roller motor turning on. - Causes: Poor contact in the connector terminals.

Defective centerfold side registration motor 1.

Defective PWB.

The roller sensor, roller motor connector makes poor contact.

Defective roller sensor.

Defective roller motor.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC7 on the centerfold main PWB and the connector of centerfold side registration motor 1, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold side registration motor 1. Replace centerfold side registration motor 1.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The roller sensor, roller motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective roller sensor. Replace the roller sensor.

Defective roller motor. Replace the roller motor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8360

- Description: Centerfold main motor problem (optional center-folding unit of 3000sheet document finisher)

The motor lock signal is detected above 1 s during driving the centerfold main motor.

Slide motor problem (optional document finisher) The slide sensor does not turn on/off within specified time of the slide motor turning on. - Causes: Poor contact in the connector terminals.

Defective centerfold main motor.

Defective PWB.

The slide sensor, slide motor connector makes poor contact.

Defective slide sensor.

Defective slide motor.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC12 on the centerfold main PWB and the connector of the centerfold main motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective centerfold main motor. Replace the centerfold main motor.

Defective PWB. Replace the centerfold main PWB or finisher main PWB and check for correct operation.

The slide sensor, slide motor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective slide sensor. Replace the slide sensor.

Defective slide motor. Replace the slide motor.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8440

- Description: Sensor adjusting problem (optional document finisher)

The sensor cannot be adjusted within the specified range. - Causes: The paper entry sensor connector makes poor contact.

Defective paper entry sensor.

The optical path of the paper entry sensor is blocked by foreign matter.

Defective finisher main PWB. - Remedy: The paper entry sensor connector makes poor contact. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective paper entry sensor. Replace the paper entry sensor and check for correct operation.

The optical path of the paper entry sensor is blocked by foreign matter. Remove the foreign matter.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8460

- Description: EEPROM problem (optional document finisher)

Reading from or writing to EEPROM cannot be performed. - Causes: Defective EEPROM or finisher main PWB.

- Remedy: Replace the finisher main PWB and check for correct operation.

- Code: C8500

- Description: Mailbox communication error (optional mailbox of 3000-sheet document finisher)

Communication with the mailbox is not possible although the connection is detected. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of the connector of the mailbox and the connector YC7 on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the mailbox main PWB or finisher main PWB and check for correct operation.

- Code: C8510

- Description: Mailbox drive motor problem (optional mailbox of 3000-sheet document finisher)

The motor lock signal is detected above 500 ms during driving the mailbox drive motor. - Causes: Poor contact in the connector terminals.

Defective mailbox drive motor.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC5 on the mailbox main PWB and the connector of the mailbox drive motor, and the continuity across the connector terminals. Repair or replace if necessary.

Defective mailbox drive motor. Replace the mailbox drive motor.

Defective PWB. Replace the mailbox main PWB or finisher main PWB and check for correct operation.

- Code: C8800

- Description: Document finisher communication error (optional 3000-sheet document finisher)

A communication error from document finisher is detected 10 times in succession. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the engine PWB and the connector on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the finisher main PWB or engine PWB and check for correct operation.

- Code: C8900

- Description: Finisher backup problem (optional 3000-sheet document finisher)

Read and write data does not match 3 times in succession. - Causes: Poor contact in the connector terminals.

EEPROM installed incorrectly.

Defective finisher main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the finisher main PWB and the connector of the machine, and the continuity across the connector terminals. Repair or replace if necessary.

EEPROM installed incorrectly. Install EEPROM correctly.

Defective finisher main PWB. Replace the finisher main PWB and check for correct operation.

- Code: C8910

- Description: Punch backup problem (optional of 3000-sheet document finisher)

Read and write data does not match 3 times in succession. - Causes: Poor contact in the connector terminals.

Defective punch PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the punch PWB and the connector YC4 on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective punch PWB. Replace the punch PWB and check for correct operation.

- Code: C8920

- Description: Mailbox backup problem (optional mailbox of 3000-sheet document finisher)

Read and write data does not match. - Causes: Poor contact in the connector terminals.

Defective mailbox main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the mailbox main PWB and the connector YC7 on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

Defective mailbox main PWB. Replace the mailbox main PWB and check for correct operation.

- Code: C8930

- Description: Center-folding backup problem (optional center-folding unit of 3000sheet document finisher)

Read and write data does not match 3 times in succession. - Causes: Poor contact in the connector terminals.

EEPROM installed incorrectly.

Defective centerfold main PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector on the centerfold main PWB and the connector YC5 on the finisher main PWB, and the continuity across the connector terminals. Repair or replace if necessary.

EEPROM installed incorrectly. Install EEPROM correctly.

Defective centerfold main PWB. Replace the centerfold main PWB and check for correct operation.

- Code: C9000

- Description: DP communication problem (optional DP)

A communication error is detected. - Causes: Poor contact in the connector terminals.

Defective PWB. - Remedy: Poor contact in the connector terminals. Check the connection of connector YC6 on the ISM PWB and the connector of the DP, and the continuity across the connector terminals. Repair or replace if necessary.

Defective PWB. Replace the DP driver PWB or ISM PWB and check for correct operation.

- Code: C9040

- Description: DP lift motor going up error (optional DP) The tray upper limit switch does not turn on within 2 s of DP lift motor turning on.

- Causes: Loose connection of the DP lift motor connector.

Malfunction of the DP lift motor.

Loose connection of the tray upper limit switch connector.

Malfunction of the tray upper limit switch.

Defective DP driver PWB. - Remedy: Loose connection of the DP lift motor connector. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Malfunction of the DP lift motor. Replace the DP lift motor and check for correct operation.

Loose connection of the tray upper limit switch connector. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Malfunction of the tray upper limit switch. Replace the tray upper limit switch and check for correct operation.

Defective DP driver PWB. Replace the DP driver PWB and check for correct operation.

- Code: C9050

- Description: DP lift motor going down error (optional DP)

The tray lower limit switch does not turn on within 2 s of DP lift motor turning on. - Causes: Loose connection of the DP lift motor connector.

Malfunction of the DP lift motor.

Loose connection of the tray lower limit switch connector.

Malfunction of the tray lower limit switch.

Defective DP driver PWB. - Remedy: Loose connection of the DP lift motor connector. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Malfunction of the DP lift motor. Replace the DP lift motor and check for correct operation.

Loose connection of the tray lower limit switch connector. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Malfunction of the tray lower limit switch. Replace the tray lower limit switch and check for correct operation.

Defective DP driver PWB. Replace the DP driver PWB and check for correct operation.

- Code: C9060

- Description: DP EEPROM error (optional DP)

Read and write data does not match. Data in the specified area of the backup memory does not match the specified values. - Causes: Defective DP driver PWB.

Device damage of EEPROM. - Remedy: Defective DP driver PWB. Replace the DP driver PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: C9070

- Description: Communication problem between DP and SHD (optional DP)

A communication error is detected. - Causes: Loose connection of the SHD PWB.

Defective SHD PWB. - Remedy: Loose connection of the SHD PWB. Reinsert the connector. Also check for continuity within the connector cable. If none, remedy or replace the cable.

Defective SHD PWB. Replace the SHD PWB and check for correct operation.

- Code: C9080